Definition and Purpose of Brazing Procedure Specifications (BPS)

Brazing Procedure Specifications (BPS) are detailed instructions used during the brazing process to ensure consistency, quality, and safety. These specifications are guided by the standards set forth in QB-200 1, Section IX of the American Society of Mechanical Engineers (ASME) Boiler and Pressure Vessel Code. BPS outlines the essential variables in brazing operations, such as the base materials, filler metals, and fluxes used, as well as the temperatures, times, and methods applied. This document is crucial for maintaining uniformity in projects that involve joining metals, particularly in high-stakes industries like aerospace, automotive, and manufacturing. Understanding and following BPS helps to prevent mechanical failures and ensures compliance with industry regulations.

How to Use the Brazing Procedure Specifications (BPS) (See QB-200 1, Section IX)

When employing Brazing Procedure Specifications, start by reviewing the detailed instructions provided in QB-200 1, Section IX. This section explains the criteria and guidelines for brazing processes, which include pre-heating parameters, permissible materials, and the cooling process. Users must:

- Identify the base metals and compatible filler metals for the brazing process.

- Follow the specified temperatures and holding times to achieve optimal joint strength.

- Adhere to any specified safety protocols, such as the use of protective equipment.

- Record all pertinent variables during the process to ensure traceability and accountability.

By adhering to BPS guidelines, manufacturers and engineers can guarantee the integrity of metal joints, thus promoting product safety and compliance with regulatory standards.

Steps to Complete the Brazing Procedure Specifications (BPS)

Completing a BPS involves several critical steps to ensure thorough documentation:

-

Preparation:

- Gather all necessary materials and tools.

- Verify that all team members are familiar with QB-200 1, Section IX standards.

-

Execution:

- Follow the outlined process steps meticulously, ensuring each specified variable is adhered to.

- Monitor temperatures and times closely using calibrated equipment.

-

Documentation:

- Record all parameters such as materials used, temperatures, time intervals, and any deviations.

- Ensure that all documentation is clear and legible for future audits.

-

Review:

- Have a qualified professional review the completed BPS for accuracy and compliance.

- Make corrections or annotations as necessary.

Adhering to these steps ensures that any brazing procedure is repeatable and reliable across various applications and projects.

Key Elements of the Brazing Procedure Specifications (BPS)

A comprehensive BPS includes several critical components:

- Material Specifications: Detailed descriptions of base metals, filler metals, and fluxes.

- Process Parameters: Precise instructions for temperature ranges, heating times, and necessary equipment settings.

- Quality Assurance Measures: Checks and inspections that ensure the brazing process meets industry standards.

- Safety Procedures: Guidelines on personal protective equipment (PPE) and safe handling practices.

- Documentation Requirements: Clear instructions on how to document the brazing process for traceability.

These elements collectively ensure that the brazing operation is efficient, safe, and compliant with regulations.

Important Terms Related to Brazing Procedure Specifications (BPS)

Understanding common terms is crucial for navigating the BPS document effectively:

- Filler Metal: A metal added in the molten state to join two metals.

- Flux: A material used to prevent oxidation during the brazing process.

- Heat-Affected Zone (HAZ): The area of the base metal altered due to heating.

- Preheating: The process of heating metal prior to brazing to ensure uniform temperature.

- Post-Braze Cleaning: Removal of flux and other residues after brazing.

Familiarity with these terms enhances comprehension and execution of brazing tasks.

Who Typically Uses the Brazing Procedure Specifications (BPS) (See QB-200 1, Section IX)

Various professionals and industries rely on BPS to maintain standards:

- Manufacturing Engineers: Use BPS to guide the production of metal components.

- Quality Assurance Specialists: Ensure that brazing adheres to the specified procedure.

- Welding Technicians: Apply BPS for setting up and executing brazing tasks.

- Aerospace and Automotive Industries: Utilize specialized BPS to join critical components under precise parameters.

By employing BPS, these users can uphold superior quality and safety in their brazing processes.

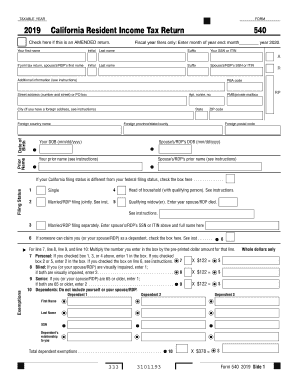

State-Specific Rules for Brazing Procedure Specifications (BPS) (See QB-200 1, Section IX)

While the ASME Boiler and Pressure Vessel Code provides a national standard, individual states may have additional requirements:

- California: Requires additional environmental impact assessments for industrial brazing projects.

- Texas: May mandate state-specific safety training for brazing personnel.

- New York: Requires state certification for certain types of industrial brazing applications.

Understanding and complying with state-specific rules ensures legal operation and maximizes safety and efficiency in brazing processes.

Legal Use of the Brazing Procedure Specifications (BPS) (See QB-200 1, Section IX)

The legal application of BPS is essential for compliance and safety:

- Industry Compliance: Ensures adherence to federal and state regulations, avoiding legal repercussions.

- Product Liability: Provides documentation that can help defend against product liability claims arising from brazing failures.

- Contract Specifications: Use BPS to meet contractual obligations with clients and partners who demand certain standards and specifications.

Using BPS legally protects organizations by ensuring high-quality outcomes and reducing the likelihood of disputes or safety incidents.