Definition and Meaning

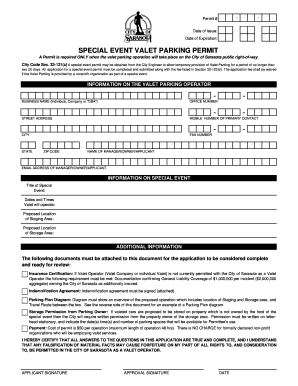

A Part Submission Warrant (PSW) is a crucial document within the automotive and manufacturing industries. It is used to submit parts to customers for approval, ensuring that specifications are met and products comply with established quality standards. The PSW includes detailed sections covering part information, supplier details, submission reasons, and the results of various compliance tests, such as those related to material, size, and functionality. This documentation facilitates communication between suppliers and clients, ensuring that all parties are aligned on the specifications and approval status of parts being supplied.

Key Elements of the PSW Documentation Example

A comprehensive PSW documentation example encompasses several essential components. These include:

- Part Information: Descriptions, part numbers, and revisions that uniquely identify the component submitted for approval.

- Supplier Details: Company name, location, and contact information for the entity submitting the part.

- Submission Reasons: Explanation of why the part is being submitted, such as a new part introduction or a change to design or production process.

- Compliance Tests: Results of tests and inspections related to standards for size, material, and functionality.

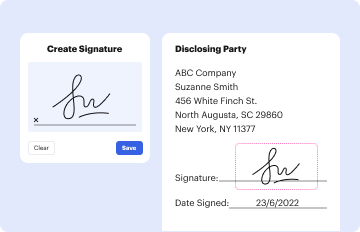

- Approval Signatures: Sections for customer and supplier signatures indicating the agreed-upon approval status.

These elements ensure that both parties have a comprehensive understanding of the submission, allowing for clear and effective communication.

Steps to Complete the PSW Documentation Example

Completing a PSW documentation example involves several steps, which are crucial for a successful submission:

-

Gather Information: Collect all necessary details about the part, including drawings, specifications, and test results.

-

Fill Out Supplier Details: Input accurate information regarding the supplier, such as company name, contact details, and the facility from which the part is being sent.

-

Explain Submission Reasons: Clearly state the reason for submission. This could be the introduction of a new part, a design change, or a shift in production.

-

Complete Compliance Tests: Conduct required tests and record the results. Ensure all tests align with compliance standards.

-

Secure Signatures: Obtain and include necessary approvals from both supplier representatives and the customer to finalize the documentation.

Each step should be completed thoroughly to ensure that the documentation is precise and that the part meets the required standards before being submitted for approval.

Who Typically Uses the PSW Documentation Example

The primary users of PSW documentation are professionals involved in the supply chain and quality assurance in manufacturing industries. These typically include:

- Suppliers: Ensure that parts comply with customer specifications and industry standards.

- Quality Assurance Teams: Verify that all necessary checks have been completed and results documented.

- Project Managers: Oversee the completion and submission processes, ensuring timelines and requirements are met.

- Customers: Review submissions to ensure received parts meet the necessary criteria before approving them for production use.

These users rely on the PSW to facilitate smooth and efficient transactions between suppliers and customers, ensuring that products adhere to the highest standards of quality and compliance.

How to Use the PSW Documentation Example

To effectively use a PSW documentation example, follow the recommended practices to streamline the approval process:

- Review Previous Submissions: Analyze past PSW forms to understand what has been accepted or rejected, aiming to replicate successful strategies.

- Collaborate with Engineers: Work closely with design and production engineers to ensure all technical data are accurate and up-to-date.

- Utilize a Template: Use a standardized template for consistency, ensuring all necessary components are included.

- Implement Checklists: Employ a checklist to verify every section of the PSW has been completed correctly and all required data are present.

By adhering to these practices, users can enhance the efficiency and accuracy of PSW submissions, reducing the likelihood of rejections or delays.

Legal Use of the PSW Documentation Example

PSW documentation holds significant legal importance, particularly in contract law and compliance. It serves as a formal record that certifies a part meets shared specifications and contractual obligations:

- Contracts: The PSW often functions as an annex in contracts, binding parties to the established specifications.

- Compliance: Ensures adherence to industry standards and regulatory requirements, which is essential for product safety and liability protection.

- Audit Trails: Creates a documented history of submissions and approvals, which can be vital for resolving disputes regarding part compliance.

The legal weight of a PSW makes it essential for manufacturers to ensure precision and thoroughness in documentation, safeguarding against legal and financial risks.

Examples of Using the PSW Documentation Example

Real-world applications of PSW documentation examples can illustrate their versatility and importance. Consider the following scenarios:

-

Automotive Manufacturing: A supplier submits a PSW for a newly designed car brake system to an auto manufacturer. The detailed compliance tests ensure the brake meets safety and performance standards.

-

Electronics Industry: A company creating electronic components provides a PSW when introducing a new circuit board. The documentation confirms that all materials and processes comply with customer specifications and environmental regulations.

-

Aerospace Production: An aerospace supplier uses PSW documentation to submit parts for a jet engine. Through detailed material and functionality tests, the parts are verified to meet stringent aviation standards.

These examples underscore the PSW's role in maintaining quality assurance across industries, protecting both suppliers and customers by ensuring parts meet agreed-upon specifications.

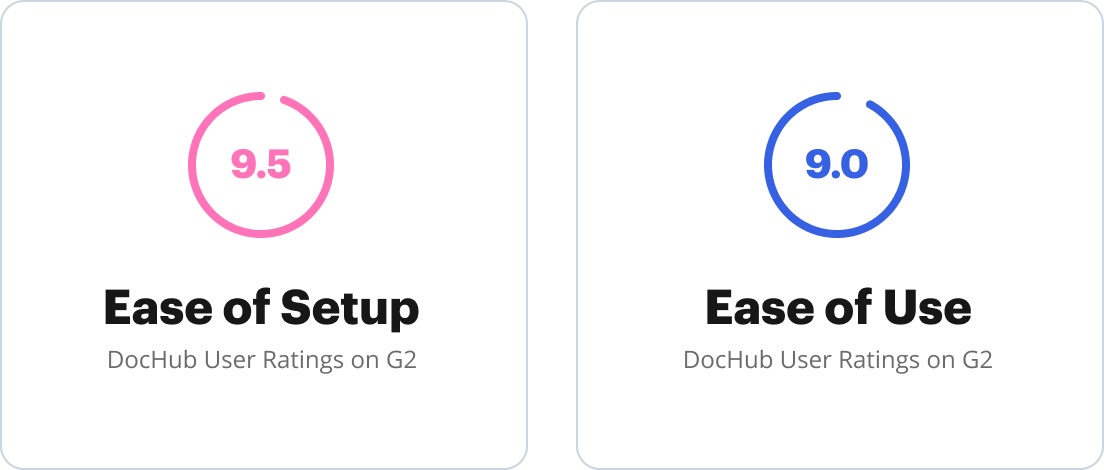

Software Compatibility with PSW Documentation Example

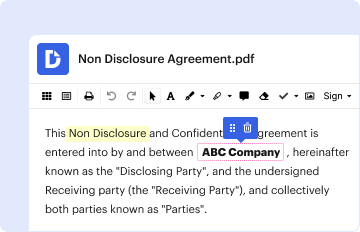

Ensuring compatibility with various software tools is crucial when handling PSW documentation. These tools facilitate efficient preparation and submission processes:

- ERP Systems: Enterprise Resource Planning software can automate data integration, helping populate PSW forms with the latest part and supplier information.

- Document Management Systems (DMS): Manage and store electronic versions of PSW documents, enabling easy retrieval and sharing.

- Spreadsheet Tools: Such as Microsoft Excel or Google Sheets, can be utilized to organize and analyze data, aiding in the completion and review of PSW forms.

Using compatible software tools aids in streamlining the submission process, improving accuracy, and ensuring compliance with standards across submissions.