Definition and Purpose of the SKF U Joint Ruler

The SKF U Joint ruler is a specialized tool designed for precise measurements of U-joints and yokes in automotive applications. Its primary purpose is to aid mechanics and technicians in identifying the correct driveshaft series and corresponding U-joint part number.

- Measurement Accuracy: The ruler facilitates accurate measurement of critical dimensions, ensuring compatibility with the appropriate U-joint. This reduces the risk of errors during replacement or repairs.

- Compatibility Verification: By using the SKF U Joint ruler, users can cross-reference measurements with the SKF U-joint catalog, ensuring that they select the correct parts for their specific vehicle make and model.

Understanding the measurement specifications is crucial in the automotive industry as incorrect components can lead to failures or safety hazards.

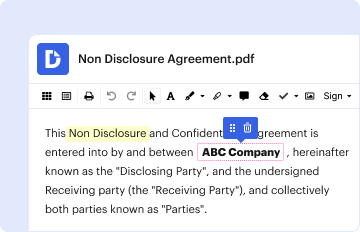

Step-by-Step Guide to Measuring with the SKF U Joint Ruler

Accurate measurement using the SKF U Joint ruler involves several key steps. Following these instructions ensures that dimensions are taken correctly, allowing for effective identification of U-joint part numbers.

- Preparation: Ensure that the U-joint or yoke is clean and free of debris, which might affect measurement.

- Positioning the Ruler: Place the SKF U Joint ruler along the U-joint, aligning it with the correct measurement points.

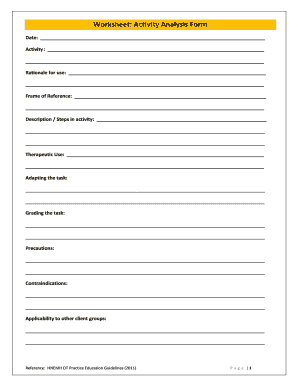

- Measurement: Take note of the dimensions specified on the ruler, focusing on:

- The width of the saddle

- The distance between the ears

- The overall length of the U-joint

- Cross-Referencing: Compare your measurements with the specifications in the SKF U-joint catalog to confirm compatibility.

- Documentation: Record the measurements and corresponding part numbers for future reference or discussion with suppliers.

Following these steps will enhance precision, reducing the likelihood of ordering incorrect replacements.

Key Features of the SKF U Joint Ruler

The SKF U Joint ruler is equipped with several features that enhance its usability and effectiveness.

- Durable Material: Typically made from high-quality materials that withstand wear and tear, ensuring long-term accuracy.

- Clear Markings: The ruler has easily readable measurements, which helps in quick referencing and reduces measurement errors.

- Versatile Use: Designed for both professional and personal use, it suits a range of vehicles from light-duty to heavy-duty applications.

- Compact Design: Its portable size allows for easy transport and storage, making it convenient for on-the-road repairs or assessments.

These features contribute to the ruler's overall functionality, making it an essential tool in automotive maintenance.

Common Applications of the SKF U Joint Ruler

The SKF U Joint ruler is widely used in various scenarios within the automotive sector. Some common applications include:

- Routine Maintenance: Technicians utilize the ruler during regular maintenance checks to examine U-joints and ensure they are within acceptable limits.

- Replacement Services: The ruler assists mechanics in quickly identifying accurate replacement parts when servicing vehicles experiencing drivetrain issues.

- Custom Fabrication: In custom vehicle builds or alterations, the ruler helps ensure that any fabricated parts meet the necessary specifications for function and safety.

Each of these uses highlights the critical role that accurate measurement plays in vehicle performance and safety.

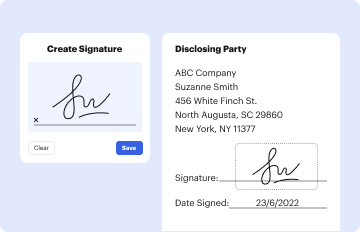

Cross-Referencing with the SKF U Joint Catalog

An important aspect of using the SKF U Joint ruler is its integration with the SKF U-joint catalog. Effective cross-referencing involves:

- Finding Part Numbers: After obtaining measurements, consult the catalog to locate corresponding U-joint part numbers based on the gathered dimensions.

- Understanding Series Numbers: The catalog provides series numbers that can help identify standard sizes and configurations for different vehicles.

- Compatibility Checks: Verify that the selected part numbers align with vehicle specifications, avoiding potential misfits or errors during installations.

This cross-referencing process is integral to ensuring that repairs are executed correctly, which promotes vehicle longevity and reliability.