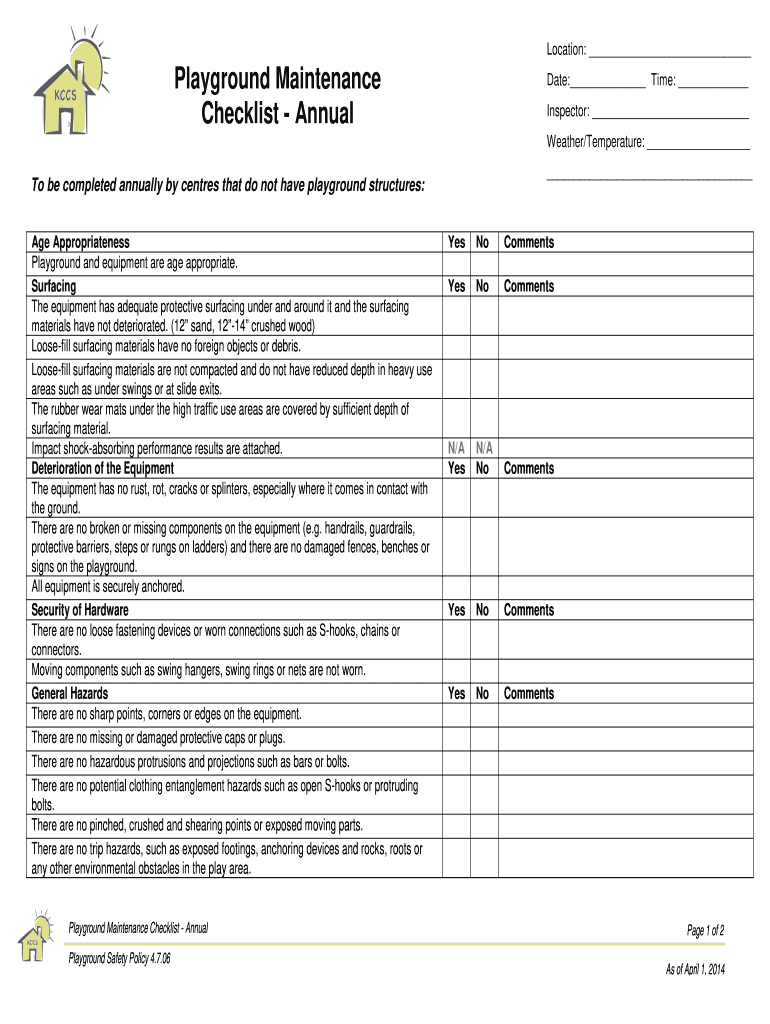

Comprehensive Playground Maintenance Checklist Overview

An effective playground maintenance checklist is essential for ensuring the safety and longevity of playground equipment. The annual checklist encompasses various criteria that inspectors need to evaluate for compliance with safety standards and maintenance requirements. This detailed overview will discuss the critical elements to include in your playground maintenance checklist.

Surfacing Evaluation

Proper surfacing is crucial for minimizing injury risk. Inspectors should assess:

- Material Integrity: Check for wear or damage in materials such as mulch, rubber mats, or sand. These surfacing options should effectively cushion falls.

- Depth Measurement: Ensure that the surfacing material meets the minimum depth requirements specified for different equipment heights. For instance, a minimum depth of twelve inches is often recommended for unpoured materials like mulch.

- Drainage Performance: Review the drainage system to prevent water pooling. Excessive moisture can lead to surface degradation or create unsafe conditions.

Equipment Condition Assessment

Regular evaluations of playground equipment are vital for identifying wear and tear. Key inspection areas include:

- Structural Integrity: Inspect the entire structure for rust, cracks, or breaks in metal components or wood. These defects should be documented and addressed promptly.

- Hardware Security: Check that all bolts, screws, and connectors are tight and secure. Loose hardware can lead to accidents and equipment failures.

- Moving Parts Functionality: Test swings, slides, and other moving parts for smooth operation. Any obstructions or defects should be fixed to prevent injuries.

General Hazards Identification

Beyond structural evaluations, inspectors should conduct a general hazard assessment. Consider the following factors:

- Protruding Objects: Identify any sharp edges or protruding pieces that may cause cuts.

- Entanglement Risks: Look for ropes, chains, or straps that could lead to entanglement. Remove any items that do not comply with safety standards.

- Blocked Access: Ensure emergency access to the playground is clear of obstructions. This is crucial for immediate response in case of an emergency.

Safety Zones and Designated Areas

Safety zones around playground equipment can significantly reduce injury risks. Inspectors should ensure:

- Appropriate Distances: Verify that there is adequate fall zone space around all equipment. For example, a minimum clearance of six feet is generally recommended for swings.

- Surface Compatibility: Confirm that safety zones use appropriate surfacing materials to cushion falls effectively. The surface type should match equipment height and intended use.

Maintenance and Upkeep Scheduling

Regular maintenance aids in preventing safety hazards and ensuring compliance with safety standards. Inspectors should establish:

- Maintenance Frequencies: Create a routine schedule for weekly, monthly, and annual inspections, detailing the necessary steps for upkeep.

- Documentation Practices: Keep records of inspections and maintenance actions taken. This documentation should include date, findings, and follow-up actions to maintain accountability.

- Repair Planning: Outline an action plan for necessary repairs or upgrades as indicated from inspection results. This includes managing budgets, materials, and contractor scheduling.

Security and Accessibility Checks

Playgrounds must be secure and accessible for all users. Ensure that:

- Fencing and Barriers: Inspect the perimeter for adequate fencing and gates that secure the area but also allow easy access for caregivers and emergency personnel.

- Accessibility Features: Evaluate access routes to ensure compliance with ADA standards, including ramps and pathways suitable for children with disabilities.

Emergency Preparedness and Procedures

Planning for emergencies is critical in playground safety. This includes:

- First Aid Availability: Confirm first aid kits are stocked and accessible near playground areas.

- Incident Reporting Mechanisms: Ensure there are established procedures for reporting and responding to accidents or hazards encountered on the playground.

Additional Considerations

In addition to the main checklist components, consider encompassing related elements:

- Educational Initiatives: Include guidance for training staff or volunteers on maintaining and inspecting playground equipment effectively.

- Community Engagement: Foster collaboration with parents and local stakeholders in the maintenance efforts. Community involvement can enhance accountability and improve playground conditions.

This annual playground maintenance checklist serves as an indispensable tool for ensuring safe play environments for children. By evaluating surfacing, equipment, hazards, zones, maintenance scheduling, security, and preparedness, grounds managers and inspectors can uphold high safety standards in playgrounds.