Definition and Meaning

The Supply Chain Management 8D Corrective Action is a rigorous problem-solving methodology designed to address and rectify nonconformance issues within supply chain processes. This structured approach is predominantly used to discover root causes of defects, implement corrective measures effectively, and prevent future occurrences. The 8D technique encourages collaboration and thorough documentation, which are instrumental in achieving sustained improvements in supply chain operations. By outlining specific phases, from team building to endorsing preventive strategies, the 8D process ensures comprehensive scrutiny and resolution of complex supply chain challenges.

Key Elements of the Supply Chain Management 8D Corrective Action

- Team Formation: Assembling a competent team with cross-functional expertise is crucial for diverse perspectives and efficient problem resolution.

- Problem Description: Clearly defining the problem to ensure all stakeholders agree on the issue that needs to be resolved.

- Containment Actions: Implementing immediate but temporary measures to contain the impact of the problem before a permanent solution is developed.

- Root Cause Analysis: In-depth investigation to identify the underlying causes of the problem using tools such as fishbone diagrams or the "5 Whys" technique.

- Corrective Action Implementation: Deploying changes to rectify the root causes of the issue effectively.

- Verification of Corrective Actions: Monitoring and testing the effectiveness of the implemented solutions to gauge their success.

- Preventive Actions: Establishing measures to prevent the identified problem from reoccurring.

- Recognition of Team Efforts: Acknowledging and documenting the contributions of team members for continuous motivation and engagement.

Steps to Complete the Supply Chain Management 8D Corrective Action

- Recognize the Problem: Gather initial data and evidence of the issue.

- Establish the Team: Select team members with diverse skills relevant to the problem.

- Describe the Problem: Use data to clearly articulate the nonconformance aspect.

- Contain Symptoms: Apply short-term measures to control the situation.

- Identify Root Causes: Utilize analytical tools to uncover the core issue.

- Select Corrective Actions: Develop action plans targeting root causes.

- Implement Solutions: Apply the chosen corrective measures.

- Prevent Recurrence: Formulate strategies to avert similar problems in the future.

- Recognize Team Contributions: Document efforts and celebrate successes.

Why Supply Chain Management 8D Corrective Action is Essential

Adopting the 8D corrective action method is critical for maintaining the integrity and efficiency of supply chain operations. This process not only enhances problem-solving capabilities but also helps organizations safeguard against potential losses and quality issues. By ensuring that corrective measures are verified and preventive actions are integrated into operations, businesses can achieve higher standards of product quality and customer satisfaction. The emphasis on collaboration and documentation throughout the process equips organizations with valuable insights for future challenges.

Who Typically Uses the Supply Chain Management 8D Corrective Action

The 8D corrective action method is predominantly utilized by supply chain managers, quality assurance teams, and operations leaders in manufacturing and logistics sectors. It is especially popular among organizations seeking to foster a proactive approach to quality management. Large corporations and multinational enterprises commonly adopt this method due to its structured approach and effectiveness in addressing multifaceted supply chain issues. However, small and medium-sized businesses can also benefit significantly from the disciplined methodology it offers.

Important Terms Related to Supply Chain Management 8D Corrective Action

- Nonconformance: Any deviation from a defined standard or expectation in a product or process.

- Root Cause Analysis: A problem-solving technique focusing on identifying the origin of a problem.

- Corrective Action: Steps taken to eliminate the causes of existing nonconformances.

- Preventive Action: Measures implemented to avoid future occurrences of a problem.

- Fishbone Diagram: A visual tool for identifying the potential causes of a problem.

Examples of Using the Supply Chain Management 8D Corrective Action

Consider a manufacturing company facing repeated delays in its product deliveries due to inconsistent supplier performance. By applying the 8D methodology, the organization assembled a team to analyze the problem, identified communication gaps and inefficient logistics processes as root causes, and implemented corrective and preventive measures, such as enhanced supplier contracts and real-time tracking systems. This approach not only resolved the delays but also improved overall supplier relationships.

Legal Use of the Supply Chain Management 8D Corrective Action

In the United States, adherence to structured problem-solving methodologies like the 8D corrective action can support organizations in maintaining compliance with industry regulations and standards, such as ISO 9001. By providing a documented and methodical approach to resolving quality-related issues, the 8D process can serve as a credible evidence of due diligence in legal or regulatory scenarios, emphasizing a company's commitment to continuous improvement and compliance.

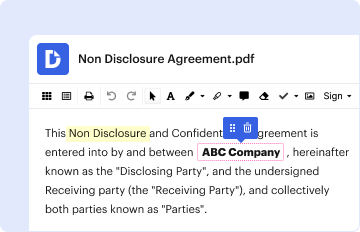

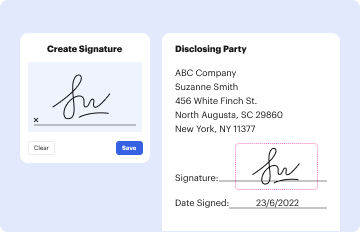

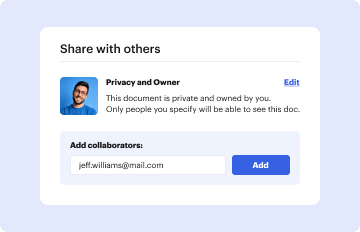

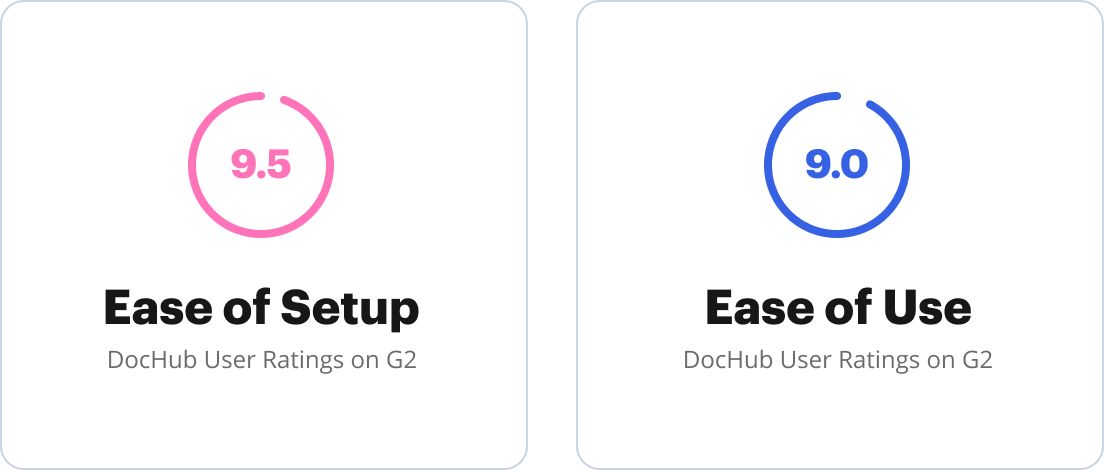

Form Submission Methods: Online vs. In-Person

Organizations can track and manage the 8D corrective action process using various tools and platforms. Digital solutions, such as DocHub, facilitate remote collaboration and documentation, making it easier to update and share 8D reports online with stakeholders. This flexibility ensures that team members can contribute to the problem-solving process without geographical constraints, promoting a more dynamic and inclusive approach to supply chain management. Conversely, some businesses may prefer traditional in-person meetings to encourage face-to-face collaboration during the 8D process.