Definition and Meaning of Manufacturing

Manufacturing is the process of converting raw materials into finished goods through various methods, including machining, assembly, and processing. It plays a crucial role in the economy by transforming resources into products used in daily life. Manufacturing integrates technologies like robotics, artificial intelligence, and the Internet of Things to enhance production efficiency and product quality.

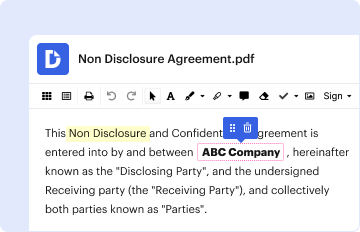

How to Use the Manufacturing Form

Utilizing the manufacturing-related form involves collecting specific data relevant to production processes. This form helps standardize workflow documentation, ensuring comprehensive details are captured for each manufacturing cycle. Users should ensure correct data input, including specifications, production dates, and quality checks, to facilitate accurate record-keeping and subsequent analysis.

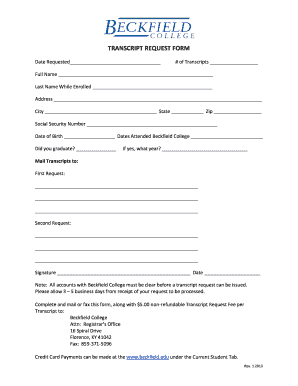

Steps to Complete the Manufacturing Form

- Gather Necessary Information: Ensure you have all required details such as material specifications, machine settings, and production schedules.

- Fill Out Basic Details: Start with identifying information such as product ID, manufacturing date, and operator name.

- Document Production Process: Include steps followed during manufacturing, highlighting any deviations from the norm.

- Quality Assurance Checks: Record any inspections or tests conducted on the finished product and note any defects or issues.

- Review and Submit: Cross-check all entries for accuracy and completeness before submission.

Key Elements of the Manufacturing Form

- Product Specifications: Details about the product, including dimensions, materials used, and technical requirements.

- Production Timeline: Start and completion dates for various stages of manufacturing.

- Quality Control Measures: Inspections conducted, results, and corrective actions if needed.

- Equipment Used: List of machinery and tools employed during production.

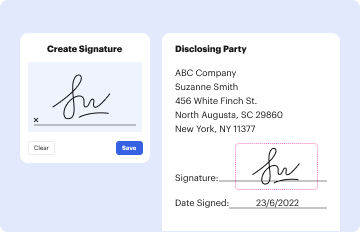

Legal Use of the Manufacturing Form

In compliance with industry regulations, manufacturing forms document production events, ensuring traceability and accountability. They are vital for audits and legal compliance, especially in regulated sectors like pharmaceuticals or food manufacturing. Proper use aligns with standards to mitigate risks and enhance operational transparency.

Who Typically Uses the Manufacturing Form

- Manufacturing Engineers: Oversee production processes and use forms to track efficiency.

- Quality Assurance Teams: Utilize these forms for documenting inspection results and maintaining product quality standards.

- Production Managers: Coordinate operations and rely on forms for planning and resource allocation.

Important Terms Related to Manufacturing

- Lean Manufacturing: A methodology focused on minimizing waste without sacrificing productivity.

- Six Sigma: A set of techniques for process improvement to reduce defects and variation.

- Just-in-Time (JIT): A production strategy to improve business return on investment by reducing in-process inventory.

State-Specific Rules for Manufacturing

Manufacturing regulations can vary by state, particularly concerning environmental impact, labor laws, and safety standards. States may also have differing tax incentives or grants for manufacturers. It's essential for businesses to understand local regulations to maintain compliance and optimize operations.

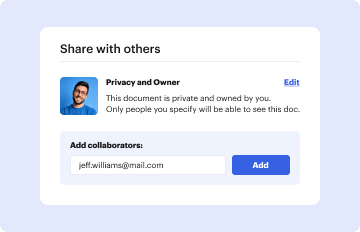

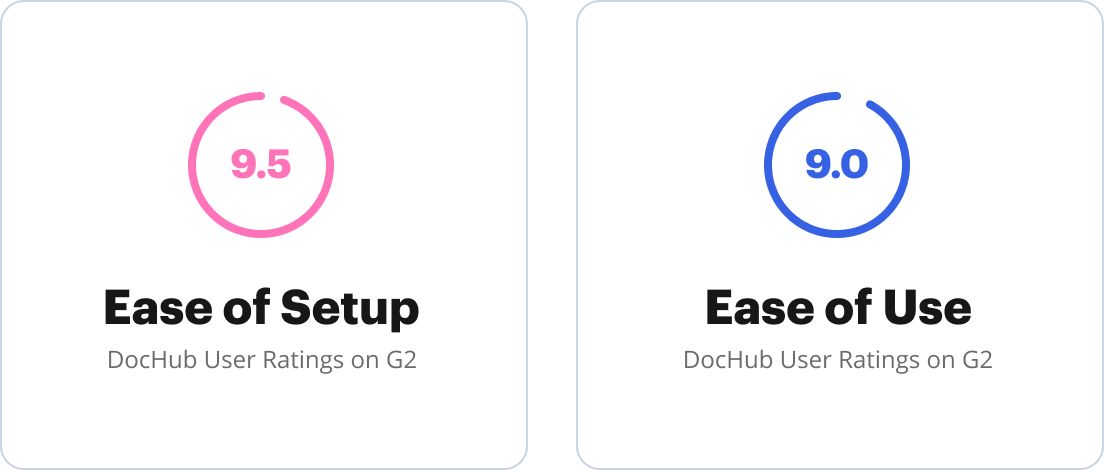

Digital vs. Paper Version

The digital version of manufacturing forms offers advantages like easier dissemination, better data accuracy, and integration with other digital systems for real-time updates. Paper versions, while traditional, can suffer from manual errors but provide a physical audit trail. Choosing between them depends on a company's infrastructure and preference for digital transformation.

Penalties for Non-Compliance

Failing to adequately complete or manage manufacturing documentation can result in legal penalties, including fines and operational shutdowns. Non-compliance with safety or environmental regulations can lead to serious consequences, underscoring the importance of meticulous documentation and adherence to manufacturing standards.