Definition & Purpose

The Aboveground Petroleum Tank Monthly Inspection Report with 6136 - ne-equip serves as a critical tool for maintaining the safety and operational status of aboveground petroleum storage tanks. It is designed in accordance with New York State regulations to systematically document the inspection of these storage tanks. The report ensures that tanks are free from leaks, corrosion, and any operational malfunctions. Inspectors use this form to evaluate the tank’s condition, ensuring compliance with environmental and safety standards, and to promptly report any anomalies that could signify potential hazards.

How to Use the Inspection Report

-

Preparation:

- Gather all necessary tools and equipment for the inspection, such as measuring devices and safety gear.

-

Visual Inspection:

- Check the tank for any visible signs of damage, such as rust or dents.

- Inspect all external components, including valves and alarms, for proper functionality.

-

Functional Tests:

- Operate the tank’s valves and safety mechanisms to ensure they work correctly.

- Confirm the operational status of alarms and overfill prevention devices.

-

Documentation:

- Record all findings on the inspection report, detailing the condition of the tank and any issues identified.

- Use the checklist to ensure no critical component is overlooked.

-

Review & Submit:

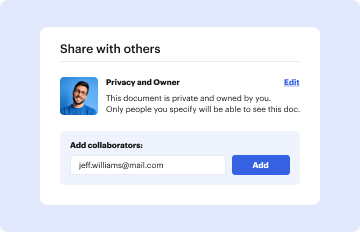

- Upon completing the inspection, review the report for accuracy.

- Submit the completed report to the appropriate regulatory authority and retain a copy for records.

Important Terms Related to the Inspection Report

- Corrosion: Degradation of materials caused by environmental reactions, particularly relevant to the metal components of storage tanks.

- Operational Status: A term used to denote whether the tank and its components are functioning as expected.

- Spills and Leaks: Unintended discharges of petroleum, requiring immediate attention and reporting as part of the inspection protocol.

- Regulatory Compliance: Adherence to state and federal environmental laws governing petroleum storage.

Key Elements of the Inspection Report

- Inspector Information: Details of the person conducting the inspection, including their qualifications and contact information.

- Tank Identification: A unique identifier for the tank being inspected to ensure traceability.

- Checklists and Observations: A detailed list aimed at confirming each aspect of the tank’s condition, including structural integrity and function of safety devices.

- Action Items: Recommendations for addressing any identified issues, such as repairs or additional monitoring requirements.

Steps to Complete the Inspection Report

-

Before the Inspection:

- Review previous inspection reports for historical issues.

- Schedule the inspection during operational downtime to avoid interruptions.

-

During the Inspection:

- Follow the checklist closely, taking detailed notes of each component checked.

- Use photographic evidence to support written observations when necessary.

-

After the Inspection:

- Immediately address any urgent safety issues discovered during the inspection.

- Summarize findings, including any corrective actions taken or planned.

-

Final Check:

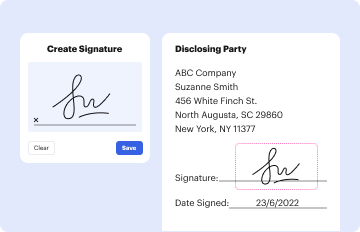

- Ensure all required fields and sections in the report are filled out completely.

- Sign and date the report to validate the inspection completion.

Legal Use Guidelines

The inspection report is not only a necessary component for regulatory compliance but also a legal document that can be referenced in the event of an environmental audit or investigation. Inspectors must ensure the information is comprehensive and accurate. Falsifying information on the report can lead to significant legal ramifications, including fines and penalties for the responsible party.

State-Specific Rules and Requirements

In New York State, specific regulations govern the maintenance and inspection of aboveground petroleum tanks. Inspectors must be familiar with these requirements to ensure adherence. This includes the frequency of inspections, specific checks mandated by state law, and the protocols for reporting spills or leaks. Failure to comply with these state-specific rules can result in substantial fines and increased scrutiny from environmental officers.

Examples of Using the Inspection Report

-

Scenario 1: Routine Inspection Finds Corrosion

- An inspector identifies corrosion during a routine inspection. The report details the extent of the corrosion and recommends immediate repairs to mitigate potential leaks.

-

Scenario 2: Valve Malfunction Detected

- A valve fails to operate correctly, triggering further investigation. The report outlines the malfunction, and maintenance is scheduled to replace the faulty valve.

-

Scenario 3: No Issues Detected

- The inspection finds all components in excellent condition. The report is filed with no action items noted, serving as a benchmark for future inspections.