Definition and Purpose of the Palltronic Flowstar IV

The Palltronic Flowstar IV is an essential integrity test instrument specifically engineered for applications within the pharmaceutical industry. It is designed to ensure compliance with industry regulations by verifying the integrity of filters used in production processes. The instrument executes various tests, such as Forward Flow and Bubble Point, to confirm the reliable performance of filtration systems. The Flowstar IV's role is to maintain high-quality pharmaceutical production by identifying any breaches in filter integrity, safeguarding product sterility.

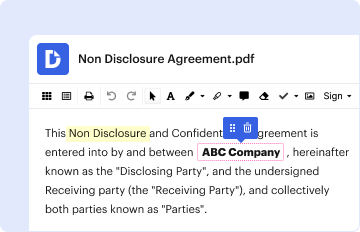

How to Use the Palltronic Flowstar IV

Using the Palltronic Flowstar IV requires an understanding of its key functionalities to conduct effective integrity testing. Follow these steps for optimal utilization:

- Preparation: Ensure the instrument is calibrated and all necessary accessories are present.

- Select Test: Choose the appropriate test type from Forward Flow, Water Intrusion, Leak Test, or Bubble Point based on the filter and application.

- Configuration: Input the required parameters like test pressure and duration into the system.

- Execution: Initiate the test and monitor results via the user interface.

- Analysis: Review the test report to determine if the filter meets the specified integrity criteria.

By adhering to these steps, users can effectively employ the Flowstar IV to maintain operational standards.

Key Elements of the Palltronic Flowstar IV

The Palltronic Flowstar IV is defined by several key elements that support its role in integrity testing:

- User Interface: Designed for ease of use, allowing operators to select tests and input parameters efficiently.

- Test Variety: Supports multiple tests such as Forward Flow, Bubble Point, and Water Intrusion, ensuring versatile application across different filtration systems.

- Data Management: Stores test results and provides detailed reports for compliance documentation.

- Automation: Streamlines test processes, reducing manual intervention and potential errors.

These elements collectively ensure reliable results while simplifying user interaction.

Legal Use of the Palltronic Flowstar IV

The Palltronic Flowstar IV adheres to industry regulations to meet legal compliance within pharmaceutical environments:

- Compliance Standards: Designed in accordance with FDA, GMP, and other international regulatory requirements.

- Validation Guide: Provides comprehensive documentation and procedures to achieve validated status for legal compliance.

- Audit Trails: Maintains detailed records of test operations and modifications, protecting against non-compliance claims.

By integrating the Flowstar IV into testing processes, pharmaceutical companies can meet stringent regulatory requirements.

Steps to Complete Testing with the Palltronic Flowstar IV

Conducting a complete test with the Palltronic Flowstar IV involves the following detailed steps:

- Setup: Install the instrument and connect it to the filtration system under scrutiny.

- Parameter Setting: Access the settings option to define test parameters suited to your filter type.

- Calibration Check: Validate that the device calibration is up-to-date to ensure accurate readings.

- Testing: Activate the instrument and initiate the prepared testing protocol.

- Monitoring and Adjustments: Observe the test progress, making any necessary adjustments in real time.

- Result Collection: Once the test is completed, retrieve the results and assess filtration system integrity.

Following these systematic steps ensures thorough testing and reliable results.

Examples of Using the Palltronic Flowstar IV

The Palltronic Flowstar IV is applied in various scenarios to ascertain filter integrity:

- Pharmaceutical Manufacturing: Ensures sterile product output by checking final product filters.

- Biopharmaceutical Processes: Validates large-scale filtration systems used for drug substance purification.

- Sterile Production Lines: Confirms the integrity of filters in heavily regulated environments requiring stringent controls.

Real-world examples underline the device's significance in maintaining production standards.

Why Should You Use the Palltronic Flowstar IV?

Using the Palltronic Flowstar IV carries significant advantages:

- Quality Assurance: Offers precise testing to ensure product quality and safety.

- Regulatory Compliance: Helps companies meet stringent industry standards and regulations.

- Cost Efficiency: Prevents costly product recalls by ensuring filter efficiency before any issues arise.

These benefits position the Flowstar IV as a critical tool in protecting both product integrity and corporate reputations.

Versions or Alternatives to the Palltronic Flowstar IV

While the Palltronic Flowstar IV is a robust choice, alternatives and previous versions exist for varying applications:

- Flowstar III: An earlier model providing basic integrity testing capabilities.

- Alternative Brands: Competing instruments offer different feature sets, such as automated systems or specialized test capabilities.

Understanding available versions and alternatives allows users to choose the most suitable option for their specific needs and preferences.