Definition and Meaning of A325 Torque

The term "A325 torque" refers to the torque values used in fastening specifications for ASTM A325, which is a standard specification for high-strength structural bolts. These bolts are commonly used in structural steel connections where high loads and tensions are involved. The torque value refers to the amount of rotational force applied to tighten the bolt to ensure adequate clamping force without over-tightening. Understanding the precise torque requirements is essential for maintaining the integrity of a structure and preventing bolt failure.

How to Use the A325 Torque

Using the correct A325 torque is crucial for ensuring the performance and safety of structural components. To apply the proper torque, follow these steps:

-

Determine Bolt Specifications: Before you begin, verify the bolt size, finish (e.g., waxed, galvanized), and specific application context to choose the correct torque value.

-

Use a Calibrated Torque Wrench: Ensure your torque wrench is calibrated for accuracy. This precision tool will help you apply the exact amount of force needed.

-

Apply Torque Gradually: Begin by tightening the bolt to approximately 25% of its final torque. Gradually increase the force in steps until the full torque is achieved. This staggered approach helps prevent uneven clamping.

-

Check for Even Tightening: Ensure all bolts in a structural component are torqued uniformly to distribute forces evenly across the joint.

-

Inspect the Joint: After torquing, visually and physically inspect the joint for any misalignment, gaps, or deformations caused by improper tightening.

Important Considerations

-

Bolt Lubrication: The presence of lubrication can affect torque values. Apply lubrication as specified in the guidelines to ensure consistent results.

-

Environmental Factors: Temperature and environmental conditions can influence material properties and, consequently, torque requirements.

Obtaining the Correct A325 Torque

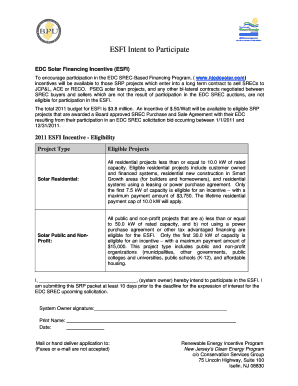

To obtain the appropriate A325 torque values, you may refer to engineering charts or documents that outline standard guidelines for different bolt sizes and grades, such as those provided by the ASTM specification for A325 bolts. These resources offer a comprehensive chart of suggested starting torque values and detail the tightening torque in foot-pounds for various bolt sizes and finishes.

- Consult Manufacturer Guidelines: Manufacturers often provide specific torque recommendations tailored to their products.

- Professional Advice: For complex or critical applications, consult a structural engineer who can provide insights based on the specific use case and environmental conditions.

Steps to Complete the A325 Torque Process

When executing the A325 torque process, adhering to a consistent approach ensures reliability and safety:

- Preparation: Gather all necessary tools and verify their accuracy, particularly the torque wrench.

- Identify Components: Determine which specific bolts require torquing and confirm their accessibility.

- Follow Sequence: Torque the bolts following a specified sequence, such as a star pattern, to reduce the risk of uneven tensions.

- Documentation: Record the torque values applied to each bolt for future reference and compliance with construction standards.

Key Elements of A325 Torque

Understanding the key elements involved in applying A325 torque helps ensure structural integrity and safety:

- Bolt Grade: ASTM A325 signifies a specific grade of high-strength bolts designed for structural applications.

- Torque Value: The specific torque value is crucial for establishing the appropriate tension without causing damage to the bolt or structure.

- Clamping Force: Proper torque application results in adequate clamping force to hold structural components together.

- Environmental Conditions: Consideration of environmental factors affects the performance of the fastening system.

Technical Terms and Their Meaning

- Foot-Pounds: A unit of measure for torque, commonly used in the United States engineering contexts, indicating the amount of force applied in a rotational direction.

- Clamping Force: The compressive force that holds two or more components together when fastened.

Examples of Using the A325 Torque

Real-world applications of A325 torque values include:

- Construction Projects: Ensuring steel beams are securely fastened in bridges and high-rise buildings.

- Industrial Machinery: Attaching critical components where vibration and heavy loads are common.

- Utility Structures: Securing wind turbine components subjected to variable environmental pressures.

Each application demands precise torque values to maintain safety standards and design specifications.

Business Types That Benefit Most from A325 Torque

Industries and business types frequently using A325 torque include:

- Construction Firms: Engaged in large-scale infrastructure projects.

- Manufacturing Companies: Producing machinery and equipment that require high-strength fastening solutions.

- Engineering Consultancies: Providing oversight for structural audits and inspections.

These sectors rely heavily on the correct application of A325 torque to satisfy regulatory demands and ensure structural reliability.