Definition & Meaning

The "Generator Maintenance Log" is an essential document used to record and track maintenance activities for a generator. Its primary function is to ensure the operational reliability and longevity of the generator by documenting routine checks and scheduled servicing tasks. Maintenance logs typically include details on engine oil, coolant, fuel levels, and other crucial components that require regular inspection. The log serves both as a historical record for maintenance personnel and as a compliance tool to demonstrate that proper care has been taken to maintain the generator in optimal condition.

Importance of Regular Maintenance

- Preventative Care: Regular updates to the log help identify potential issues before they become serious problems.

- Operational Efficiency: Ensures that the generator runs efficiently, potentially lowering fuel consumption and reducing wear and tear.

- Compliance and Warranty: Keeping a detailed record may be necessary for warranty claims and compliance with specific regulations or industry standards.

How to Use the Generator Maintenance Log

The effective use of a Generator Maintenance Log requires systematic recording and updating of maintenance activities.

Steps to Maintain the Log

- Initial Setup: Begin by documenting the generator’s specifications, including the make, model, serial number, and location.

- Routine Checks: Record daily checks for oil levels, coolant, and fuel, noting any discrepancies or issues.

- Scheduled Maintenance: Detail periodic maintenance tasks such as oil changes, filter replacements, and system checks.

- Repairs and Adjustments: Log any repairs or adjustments needed, why they were necessary, and how they were addressed.

- Final Verification: After each entry, verify accuracy and completeness before returning the generator to service.

Important Considerations

- Always adhere to manufacturer recommendations when documenting maintenance activities.

- Use clear, concise language to detail observations and actions taken.

- Ensure entries are made immediately after tasks are completed to maintain accuracy.

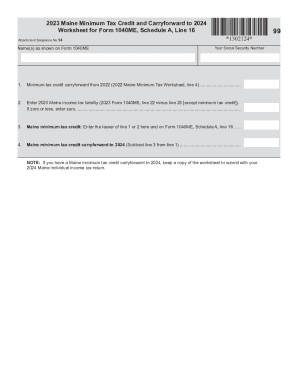

Key Elements of the Generator Maintenance Log

A comprehensive Generator Maintenance Log includes several critical elements that should be consistently documented.

Essential Components

- Date and Time: Record each maintenance activity's date and time to ensure chronological accuracy.

- Personnel: Name or initials of the person performing the maintenance task for accountability and traceability.

- Detailed Observations: Specific readings and observations, such as oil pressure levels, coolant temperature, and any visual wear or damage.

- Actions Taken: A description of any actions taken, including repairs, adjustments, or parts replaced.

- Next Steps: Recommended future actions or follow-up checks required to ensure ongoing reliability.

Benefits of Comprehensive Documentation

- Facilitates smoother transitions between maintenance personnel by providing a clear historical record.

- Enhances diagnostic efficiency by accurately reflecting past issues and resolutions.

- Support regulatory compliance and organizational protocols for maintenance activities.

Steps to Complete the Generator Maintenance Log

Effective completion of a Generator Maintenance Log involves adherence to structured steps to ensure thorough documentation.

Step-by-Step Process

- Gather Information: Before commencing maintenance, ensure all necessary tools and manuals are on hand.

- Conduct Inspection: Perform a detailed inspection according to the schedule, focusing on engine components, fluid levels, and electrical systems.

- Document Findings: Use clear terminology to record observed conditions and any anomalies detected during inspection.

- Execute Maintenance: Carry out all required maintenance activities, referring to manufacturer guidelines as needed.

- Finalize Entry: Complete the log entry by signing off and noting any required future actions.

Common Errors to Avoid

- Omitting critical details, such as specific measurements or adjustments made.

- Failing to update entries promptly, leading to inaccurate records.

- Neglecting to record negative findings or seemingly minor issues that might indicate underlying problems.

Who Typically Uses the Generator Maintenance Log

The Generator Maintenance Log is utilized by a range of individuals and organizations keen on maintaining generator efficiency and reliability.

Primary Users

- Facility Managers: Responsible for overseeing equipment maintenance in commercial or industrial settings.

- Maintenance Technicians: Utilize the log to guide and document their daily and periodic maintenance tasks.

- Compliance Officers: Review log entries as part of compliance audits to ensure adherence to regulations and standards.

Role-Specific Responsibilities

- Facility managers may use the log for planning and budgeting future maintenance tasks.

- Maintenance technicians rely on the log to ensure consistency and thoroughness in maintenance practices.

- Compliance officers verify logs to confirm all required maintenance is performed timely and accurately.

Examples of Using the Generator Maintenance Log

Real-world examples of using a Generator Maintenance Log illustrate its utility and necessity across various scenarios.

Case Studies

- Emergency Preparedness: In a hospital setting, the maintenance log ensures backup generators function optimally, critical for patient safety during power outages.

- Industrial Sites: On construction sites, logs help maintain equipment usability and prevent costly downtime due to generator failure.

- Residential Complexes: Apartment complexes use logs to ensure standby generators are ready to supply power during electrical failures, maintaining tenant satisfaction.

Lessons Learned

- Routine log updates reduce unexpected failures and associated repair costs.

- Detailed logs support faster troubleshooting by providing historical insight into recurring issues.

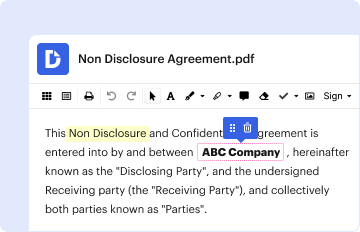

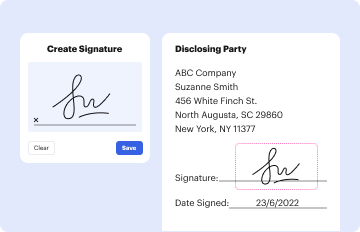

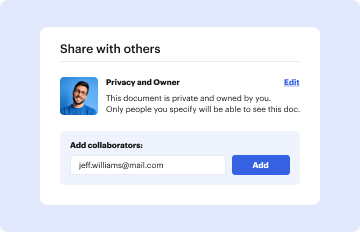

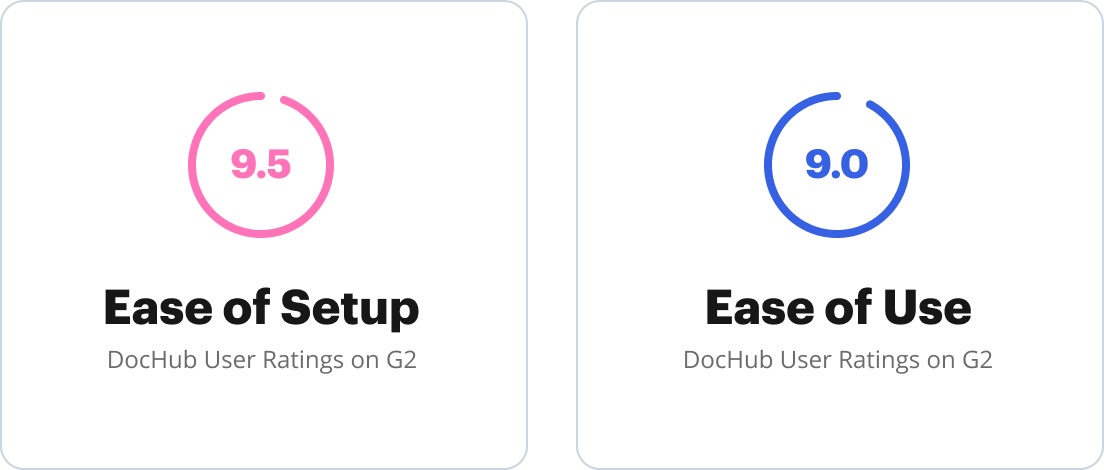

Digital vs. Paper Version

The choice between a digital or paper Generator Maintenance Log can impact ease of use and accessibility.

Digital Logs

- Advantages: Easily shareable among teams, less prone to damage or loss, efficient searching through historical data.

- Integration: Can be integrated with mobile devices for real-time updates and alerts.

- Security: Often more secure with encryption and access controls.

Paper Logs

- Advantages: No need for electronic devices, simple to implement without additional software.

- Challenges: Prone to physical damage, less environmentally friendly, more challenging to search through large volumes of data.

Considerations

- Choose the format that aligns with your operational needs, ensuring ease of use and accessibility for all users.

- Evaluate cost and resource availability when deciding between a digital and paper log.