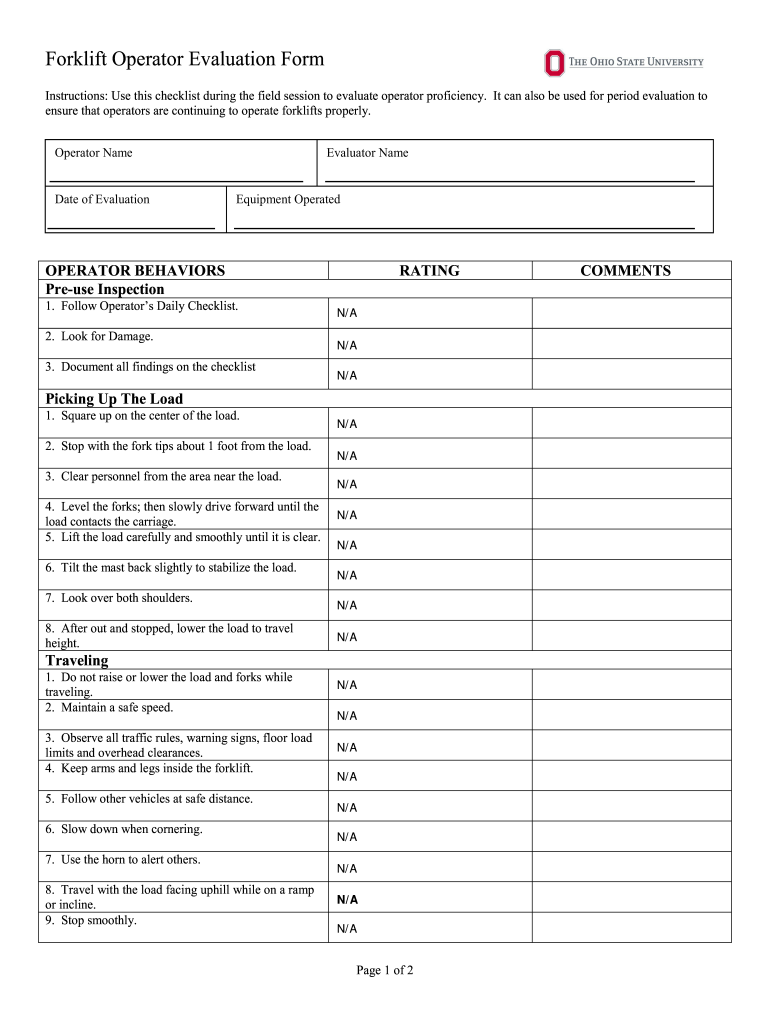

Definition and Importance of the Ohio Forklift Operator Evaluation

The Ohio forklift operator evaluation is a formal assessment designed to determine a forklift operator's capability to operate equipment safely and effectively. This evaluation is critical in ensuring that operators adhere to safety standards set forth by OSHA (Occupational Safety and Health Administration) and other regulatory bodies. The evaluation typically involves both a written test and a practical assessment, wherein operators are required to demonstrate their skills in real-time scenarios, such as maneuvering a forklift in a designated area while observing safety protocols.

Comprehensive assessments cover essential areas such as pre-operation checks, safe load handling, traveling procedures, and parking. These areas are crucial for operators to mitigate risks associated with forklift operation. Conducting regular evaluations is not only a best practice in maintaining workplace safety but is often a legal requirement for employers in Ohio to ensure that all operators are certified and qualified to perform their duties.

Steps to Complete the Ohio Forklift Operator Evaluation

Completing the Ohio forklift operator evaluation involves several critical steps to ensure thoroughness and compliance with regulatory requirements.

-

Preparation of Materials: Gather all necessary documents, including the forklift operator evaluation form, safety manuals, and instructional materials. It is important to ensure that all employees are aware of the guidelines provided by OSHA and any state-specific regulations.

-

Conduct Written Test: Administer a written evaluation covering important safety topics, including the regulations and safety practices relevant to forklift operation. This test should encapsulate questions regarding load limits, operating environment, and emergency procedures.

-

Practical Assessment: Following the written test, conduct a hands-on practical evaluation. This should occur in a safe area where operators can demonstrate their skills in real-world situations. Evaluators need to focus on inspection techniques, the ability to safely handle loads, effective use of controls, and maintaining safety measures throughout the operational process.

-

Documentation of Results: After completing both the written and practical tests, assessors must document the results on the forklift operator evaluation form. Include ratings on operator skills and comments on areas that require improvement, which aids in future training endeavors.

-

Certification Issuance: If operators meet the necessary standards, issue certifications that affirm they are qualified to operate a forklift. Recordkeeping is essential for compliance and for future evaluations, ensuring that all records are kept updated according to OSHA requirements.

Key Elements of the Ohio Forklift Operator Evaluation

Understanding the key elements of the Ohio forklift operator evaluation provides context on how to effectively assess operators while adhering to safety regulations.

-

Pre-Use Inspection Checklist: This forms the backbone of safe operations. Operators must be familiar with this checklist, which includes checking the operational integrity of the equipment before any use.

-

Loading and Unloading Procedures: Evaluators must assess the operator's ability to handle loads safely, which includes understanding weight limits, load stability, and securing loads during transport. This element is crucial to prevent accidents and ensure safe practices.

-

Driving Techniques: Operators should be evaluated on their driving skills, including techniques for navigating tight spaces, reversing, and proper speed control. Safe driving practices directly impact overall safety in the workplace.

-

Parking and Securing the Forklift: This includes how operators park the equipment, elevate the forks to a safe position, and secure it when not in use. Proper parking procedures prevent unauthorized use and potential accidents.

-

Emergency Procedures: Evaluators must gauge operators’ understanding of emergency procedures. This includes knowing how to respond to hazards, equipment failures, and potential accidents while operating the forklift.

-

Legal Compliance: Operators must be familiar with local regulations and OSHA standards to ensure compliance. This demonstrates their readiness for safe operations.

State-Specific Rules for the Ohio Forklift Operator Evaluation

In Ohio, specific rules govern the forklift operator evaluation process. These regulations are essential in maintaining safety standards and ensuring compliance with OSHA requirements.

-

Training and Certification Requirements: Ohio law mandates that all forklift operators undergo formal training and evaluation. Training programs should adhere to OSHA's guidelines to ensure comprehensive coverage of operational protocols.

-

Frequency of Evaluations: Employers are required to conduct evaluations regularly, typically on an annual basis, or whenever a significant change in operation occurs. This is especially important for operators who have not recently demonstrated their skills.

-

Documentation and Record-Keeping: Employers must maintain accurate records of evaluations and training sessions completed by each operator. These records serve as proof of compliance during audits or inspections by regulatory bodies.

-

Safety Standards: Ohio-specific safety standards may differ from federal regulations, especially in terms of local industry practices. Operators should be familiar with these to ensure that they meet the state's requirements.

Examples of Using the Ohio Forklift Operator Evaluation

Real-world illustrations of how the Ohio forklift operator evaluation is applied help to showcase its significance in diverse workplace settings.

-

Manufacturing Facilities: In manufacturing, operators are often required to move materials and products efficiently. An evaluation can ensure that they practice safe load handling and are adept at navigating complex manufacturing environments with precision.

-

Warehouse Operations: Warehouses rely heavily on forklift operations for inventory management. Regular evaluations help ensure that operators can efficiently manage stock while following safety protocols, reducing the risk of accidents occurring during busy shifts.

-

Construction Sites: Forklift operators on construction sites must be equipped to handle various materials and operate in dynamic environments. Evaluations focused on real-life scenarios help prepare operators for the complexities of construction tasks.

-

Distribution Centers: In distribution centers, operators handle large volumes of goods. Evaluations can focus on quick decision-making and safe transport techniques to ensure both efficiency and safety in high-pressure situations.

By understanding these elements and their implications, organizations can maintain a safe working environment while successfully training and evaluating their forklift operators in compliance with relevant laws and regulations.