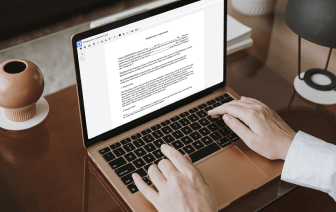

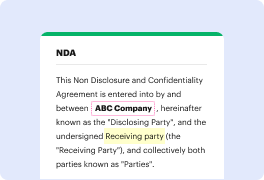

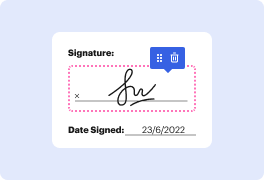

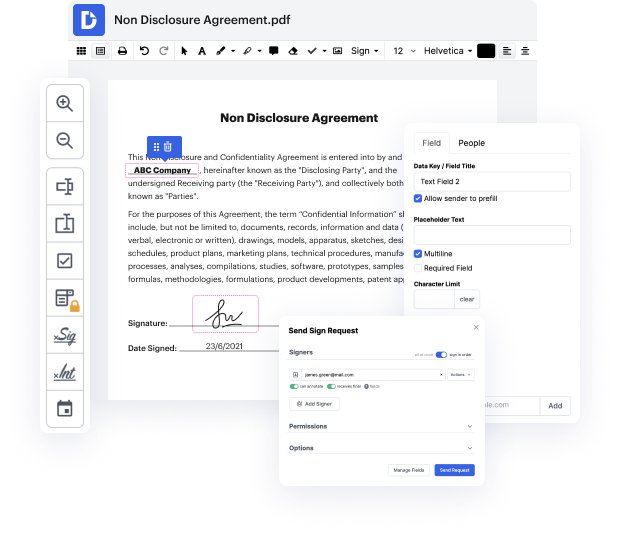

You no longer have to worry about how to work in spot in OSHEET. Our comprehensive solution provides straightforward and fast document management, enabling you to work on OSHEET files in a few moments instead of hours or days. Our service covers all the features you need: merging, inserting fillable fields, signing documents legally, inserting symbols, and so on. You don't need to install additional software or bother with pricey programs requiring a powerful device. With only two clicks in your browser, you can access everything you need.

Start now and handle all different types of forms like a pro!

resistance welding resistance is the property of the conductor by the virtue of which it resists the flow of electrons that is the flow of current through it this resistance to the flow of electrons creates friction and heat this heat generated is then used to join the two similar or dissimilar metals by melting and forming a bond between them types of resistance welding processes 1. spot welding 2. seam welding spot welding spot welding is also known as the resistance spot welding process it is used to weld thin sheets of metal together by applying pressure the heat required for welding is generated by resistance to the flow of current through the electrode working principle the welding electrodes are made up of copper which is a good conductor of electricity the movable and fixed electrodes of the spot welding machine are held in pressure on either side of a pair of plates to be welded together as the current passes it experiences the resistance between the electrode and workpiece co