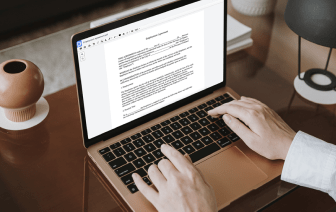

People frequently need to wipe attachment in WRF when working with forms. Unfortunately, few programs offer the tools you need to complete this task. To do something like this typically requires changing between a couple of software packages, which take time and effort. Thankfully, there is a platform that is applicable for almost any job: DocHub.

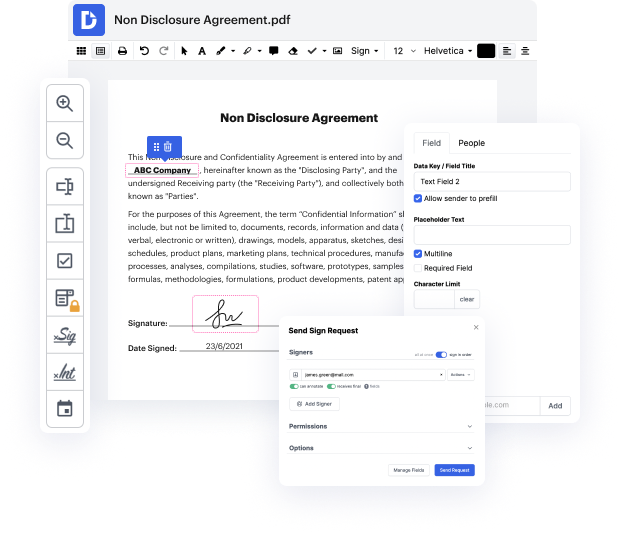

DocHub is an appropriately-built PDF editor with a full set of useful capabilities in one place. Editing, approving, and sharing documents is simple with our online solution, which you can access from any internet-connected device.

By following these five basic steps, you'll have your revised WRF rapidly. The intuitive interface makes the process fast and effective - stopping jumping between windows. Start using DocHub now!

WELCOME TO SYSTEM SPOTLIGHT, GIVING YOU AN IN DEPTH LOOK AT SHUTTLEWORTHS MORE ADVANCED PRODUCT HANDLING SYSTEMS AND CONVEYOR APPLICATIONS. IN THIS VIDEO, WE WILL SHOWCASE A SOLUTION FOR ONE OF OUR CUSTOMERS THAT WANTED DIVIDE AND TRANSPORT UNWRAPPED STACKS OF WET WIPES TO A CUSTOMER SUPPLIED WRAPPER AT A RATE OF 80 PRODUCTS PER MINUTE. PRODUCTS ENTER THE SYSTEM FROM THE CUSTOMERS STACKER WITH A 5 INCH GAP BETWEEN STACKS AND TRANSPORTED TO A ONE TO TWO DIVERTER DESIGNED AND CREATED BY SHUTTLEWORTH. THE BELT TO BELT DIVERTER HAS 3 MODES OF OPERATION. THE FIRST MODE IS LANE BALANCING BETWEEN THE TWO LANES FEEDING THE CUSTOMER SUPPLIED WRAPPER. . THE SECOND AND THIRD MODES WILL DIVERT TO A DEDICATED LANE IF THE WRAPPER ON THE OTHER LANE IS BEING SERVICED. IF TRAFFIC SENSORS DETECT A STOPPAGE IN ONE OF THE LANES, THE DIVERTER WILL AUTOMATICALLY DIVERT ALL PRODUCT TO THE OTHER LANE AND EVEN LANE BALANCING WILL RESUME ONCE THE STOPPAGE IS CLEARED. WRAPPED PRODUCTS EXIT THE CUSTOMER SUPPLIE