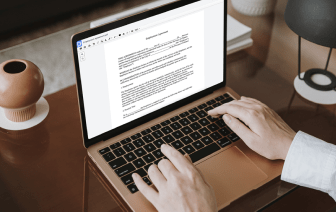

Document generation and approval are a core priority of every firm. Whether working with large bulks of documents or a distinct contract, you have to remain at the top of your productiveness. Choosing a ideal online platform that tackles your most typical file generation and approval problems could result in quite a lot of work. A lot of online apps offer you merely a restricted list of editing and eSignature capabilities, some of which could possibly be beneficial to manage WPT formatting. A platform that deals with any formatting and task will be a excellent choice when selecting application.

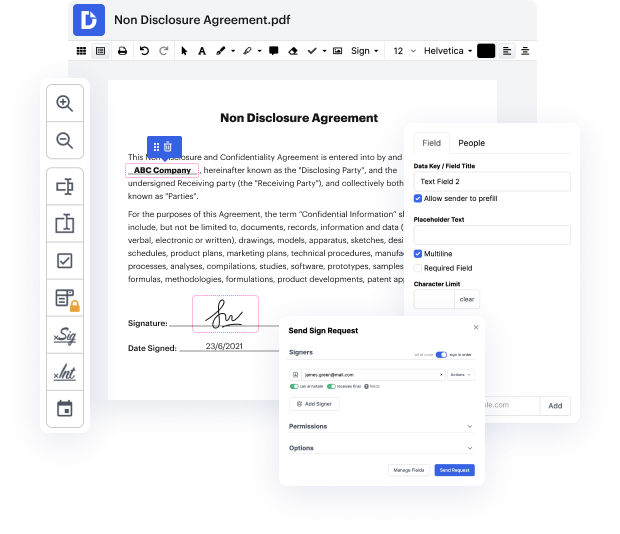

Get file administration and generation to another level of straightforwardness and sophistication without picking an difficult user interface or costly subscription options. DocHub gives you tools and features to deal effectively with all of file types, including WPT, and perform tasks of any complexity. Modify, manage, and produce reusable fillable forms without effort. Get full freedom and flexibility to inlay logo in WPT at any moment and safely store all your complete files in your account or one of many possible integrated cloud storage apps.

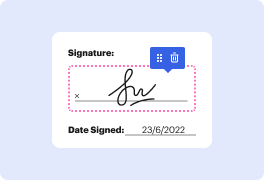

DocHub offers loss-free editing, eSignaturel collection, and WPT administration on a professional levels. You do not need to go through tedious guides and spend countless hours finding out the application. Make top-tier safe file editing a standard process for your everyday workflows.

today there you going and welcome to my workshop so today were going to do something a little bit complex what were actually going to do is were going to make an inlay with a laser so that means were gonna actually cut the pieces out like this and then etch out a negative in a piece of oak and lay it in machining often see if we can make a perfect inlay you come in you can make inlays with it CNC routers quite successfully but you cant get my sharp corners with it really not with an end mill so we do it with a laser so what we need to do is find out the settings of the laser to be able to first of all cut this out perfectly and then etch out a negative in oak and this material is [Music] one-point-five just a little bit over 1.5 millimeters which is 61 fell alright for those of you who work in thousandths of an inch or inches so we need to work out with a test subject a test part how much power speed we need to be able to machine that out of oak and cut it out of this this is you