Definition and Meaning of the Preventive Maintenance Checklist PDF

A preventive maintenance checklist PDF is a structured document that outlines routine inspection and maintenance tasks for equipment or facilities. Its primary purpose is to help organizations ensure that all essential maintenance actions are performed on a regular basis, thus preventing equipment failure and enhancing operational efficiency. This checklist serves as a tool for tracking maintenance activities, documenting completed tasks, and identifying areas needing attention.

The contents of a preventive maintenance checklist may vary based on the specific type of equipment or facility. Common categories include:

- Mechanical Systems: Covers areas like pumps, motors, and compressors.

- Electrical Systems: Involves checks on wiring, connections, and circuit breakers.

- HVAC Systems: Includes filter changes, inspections of ductwork, and thermostat calibrations.

- Plumbing: Entails checking for leaks and ensuring proper flow.

- Safety Equipment: Focuses on fire alarms, extinguishers, and emergency exits.

Each category may contain specific tasks with set frequencies for completion, ensuring that nothing is overlooked.

How to Use the Preventive Maintenance Checklist PDF

Using a preventive maintenance checklist PDF involves several straightforward steps that help streamline the process of maintenance management. The ability to follow this checklist ensures systematic inspection and upkeep of crucial systems and equipment, reducing the likelihood of unexpected failures.

-

Download the Checklist: Obtain the preventive maintenance checklist PDF from a reliable source, ensuring it is tailored to your specific industry needs.

-

Review Required Tasks: Familiarize yourself with the tasks outlined in the checklist. Each task should have a designated frequency for completion.

-

Schedule Maintenance Activities: Integrate the checklist tasks into your regular maintenance schedule. It can be beneficial to use calendar reminders for monthly or quarterly tasks.

-

Perform Inspections: Carry out inspections as listed, marking each task as complete on the checklist. This step may involve visual inspections or performance tests of the equipment.

-

Document Findings: Use the checklist to document any issues encountered during the maintenance. This documentation serves as a record for future reference and helps inform decisions about repairs or upgrades.

-

Review and Update: Regularly review the checklist to adapt to any changes in operational needs or machinery. Update frequencies for tasks as necessary, based on the equipment performance.

Important Terms Related to Preventive Maintenance Checklist PDF

Understanding the terminology associated with preventive maintenance is crucial for effective use of checklists and maintenance protocols. Here are several key terms:

-

Preventive Maintenance: Actions taken to prevent equipment failure before it occurs. This can include inspections, servicing, and parts replacements.

-

Predictive Maintenance: Maintenance based on the actual condition of equipment, often through data and monitoring technologies, aiming to predict failures.

-

Corrective Maintenance: Repairs carried out to correct a problem once it has occurred, often following a failure.

-

Maintenance Schedule: A documented timeline detailing when specific maintenance tasks should be performed.

-

Service Level Agreement (SLA): A commitment between service providers and clients that outlines expected service levels and response times for maintenance.

Understanding these terms assists individuals and organizations in effectively interpreting and employing the preventive maintenance checklist PDF in their operations.

Key Elements of the Preventive Maintenance Checklist PDF

A comprehensive preventive maintenance checklist PDF consists of several key elements that contribute to its effectiveness. These elements ensure that the checklist is practical, accessible, and relevant to users.

-

Task Descriptions: Clear and concise descriptions of each maintenance activity required, ensuring all users can understand what needs to be done.

-

Frequency of Tasks: Specific intervals at which each task should be completed, such as daily, weekly, monthly, or annually, to maintain the performance of the equipment.

-

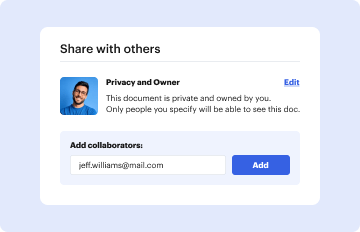

Responsible Personnel: Identification of who is responsible for carrying out each task, ensuring accountability and oversight.

-

Date of Completion: Space for recording when tasks were completed, which aids in tracking maintenance history and compliance.

-

Comments Section: A field for additional notes or observations about the equipment condition, which can provide context for future maintenance decisions.

-

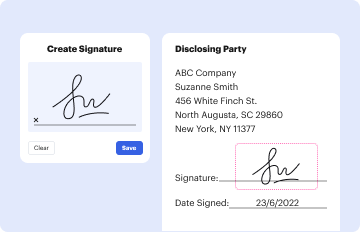

Signatures: Best practices may include a section for the maintenance personnel to sign off after task completion, documenting accountability.

Integrating these elements into the checklist enhances usability and effectiveness, facilitating systematic maintenance.

Examples of Using the Preventive Maintenance Checklist PDF

To effectively implement a preventive maintenance checklist PDF, consider the following illustrative examples from various industries:

-

Manufacturing Facility: A weekly checklist might include tasks such as inspecting machine fluids, checking electrical connections, and cleaning conveyor systems. Each task can be assigned to specific maintenance staff who document completion.

-

Healthcare Facility: In this context, a monthly checklist may ensure that medical equipment is calibrated properly, sterilization processes are performed, and safety alarms are tested. Documentation is crucial for compliance with health regulations.

-

Property Management: A quarterly checklist could cover tasks like inspecting HVAC systems, checking plumbing for leaks, and reviewing safety equipment such as fire extinguishers. This helps maintain the safety and comfort of tenants.

These examples highlight the versatility of the preventive maintenance checklist and its applicability across different operational contexts. Implementing the checklist appropriately can lead to improved efficiency and equipment reliability.