Definition and Meaning of the GMP Form

The GMP form, or Good Manufacturing Practice form, is a standardized document typically used by companies within the food, pharmaceutical, and cosmetic industries to ensure compliance with industry-specific regulatory standards that govern the quality and safety of product manufacturing processes. This form is instrumental in maintaining consistent production and quality control among manufacturers to mitigate risks associated with contamination, mislabeling, and defects. It outlines crucial aspects of manufacturing processes, such as equipment calibration, employee training, quality assurance procedures, and environmental hygiene measures.

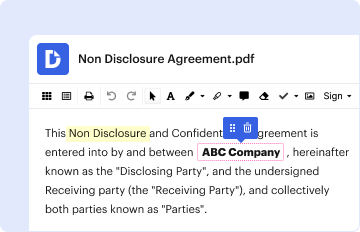

How to Use the GMP Form

To effectively utilize the GMP form, organizations must integrate it into their regular operations by maintaining thorough documentation of all manufacturing activities. This involves recording details such as batch numbers, production dates, equipment used, and the personnel involved in each phase of the manufacturing process. These records serve as a historical account to ensure that all procedures are uniformly followed and can be reproduced for any audits or inspections. Additionally, the form should be regularly reviewed and updated to reflect any changes in regulatory requirements or internal procedures.

How to Obtain the GMP Form

Organizations can obtain the GMP form through several channels, primarily through regulatory bodies such as the Food and Drug Administration (FDA) in the United States or equivalent entities globally responsible for enforcing compliance standards. Additionally, the form may be provided by industry associations or available as templates through professional documentation and compliance software platforms. Some businesses may choose to develop customized versions of the GMP form to better fit their specific operational needs while still meeting regulatory standards.

Steps to Complete the GMP Form

- Identify Applicable Processes: Determine which manufacturing processes must be documented using the GMP form based on regulatory requirements.

- Gather Relevant Data: Collect detailed information about each stage of the manufacturing process, including materials used, batch numbers, and employee roles.

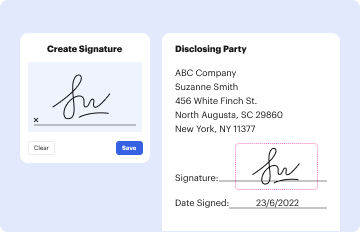

- Document Procedures: Accurately fill out the GMP form with step-by-step procedures, ensuring that all critical control points are addressed.

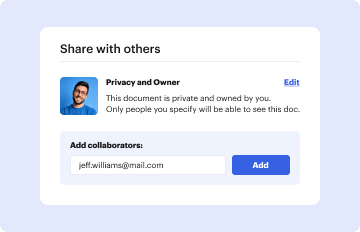

- Review and Verify Information: Cross-check the form's contents with supervisors or quality assurance personnel to confirm accuracy and completeness.

- Submit for Approval: Forward the completed form to the designated compliance officer or regulatory body for official approval and records.

Why Should You Use the GMP Form

Utilizing the GMP form is crucial for maintaining product quality and safety standards, thereby protecting consumers and mitigating potential legal liabilities. The form helps ensure adherence to industry regulations, thereby fostering trust among stakeholders, including customers, suppliers, and regulatory authorities. Proper use of the GMP form also aids in identifying process inefficiencies and instigating continuous improvements, which can lead to cost savings and higher production yields over time.

Who Typically Uses the GMP Form

The GMP form is commonly employed by quality assurance managers, manufacturing supervisors, compliance officers, and other personnel responsible for overseeing production processes within companies involved in sectors such as pharmaceuticals, food and beverage production, and cosmetics. Each of these roles plays a vital part in ensuring that all components of the manufacturing process comply with Good Manufacturing Practice standards.

Important Terms Related to the GMP Form

- Batch Record: A detailed documentation of a specific quantity of a product manufactured in a production cycle, including all relevant data and quality checks.

- Standard Operating Procedure (SOP): Descriptions of processes that detail step-by-step instructions on performing various tasks to ensure consistency and compliance.

- Validation: The process of establishing documented evidence that provides high assurance a specific process will consistently produce a result meeting predetermined specifications.

Key Elements of the GMP Form

Some essential elements of the GMP form include sections for documenting production protocols, quality control measures, equipment maintenance schedules, and employee training records. It also encompasses guidelines for managing deviations from approved procedures, conducting risk assessments, and implementing corrective actions. Each element plays a critical role in ensuring comprehensive coverage of all aspects necessary for maintaining good manufacturing practices.