People frequently need to work in spot in ODM when managing forms. Unfortunately, few programs provide the tools you need to accomplish this task. To do something like this normally involves switching between a couple of software applications, which take time and effort. Luckily, there is a service that suits almost any job: DocHub.

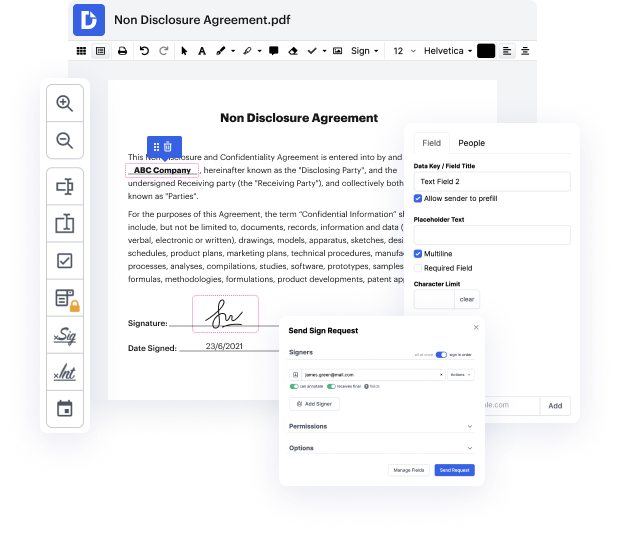

DocHub is a perfectly-built PDF editor with a complete set of useful functions in one place. Modifying, signing, and sharing paperwork is easy with our online tool, which you can use from any online device.

By following these five simple steps, you'll have your revised ODM quickly. The user-friendly interface makes the process fast and efficient - stopping jumping between windows. Start using DocHub now!

resistance welding resistance is the property of the conductor by the virtue of which it resists the flow of electrons that is the flow of current through it this resistance to the flow of electrons creates friction and heat this heat generated is then used to join the two similar or dissimilar metals by melting and forming a bond between them types of resistance welding processes 1. spot welding 2. seam welding spot welding spot welding is also known as the resistance spot welding process it is used to weld thin sheets of metal together by applying pressure the heat required for welding is generated by resistance to the flow of current through the electrode working principle the welding electrodes are made up of copper which is a good conductor of electricity the movable and fixed electrodes of the spot welding machine are held in pressure on either side of a pair of plates to be welded together as the current passes it experiences the resistance between the electrode and workpiece co