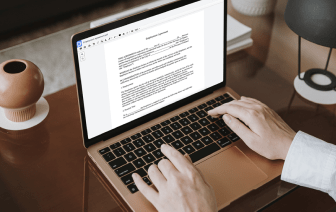

Not all formats, such as EGT, are designed to be effortlessly edited. Even though a lot of capabilities can help us tweak all document formats, no one has yet invented an actual all-size-fits-all tool.

DocHub gives a straightforward and streamlined tool for editing, managing, and storing documents in the most popular formats. You don't have to be a technology-savvy user to undo effect in EGT or make other tweaks. DocHub is robust enough to make the process easy for everyone.

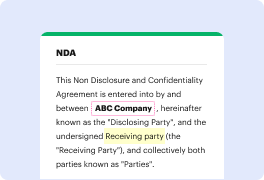

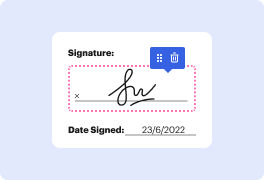

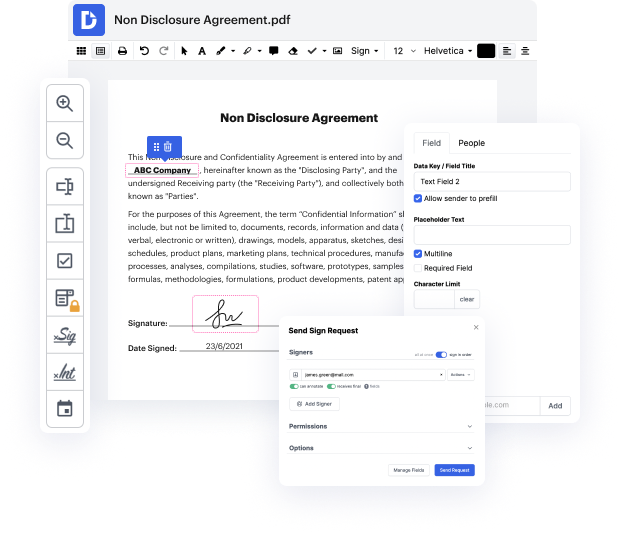

Our tool enables you to change and tweak documents, send data back and forth, generate interactive documents for information collection, encrypt and safeguard documents, and set up eSignature workflows. Moreover, you can also generate templates from documents you utilize frequently.

You’ll find a great deal of other functionality inside DocHub, including integrations that let you link your EGT document to a variety productivity apps.

DocHub is an intuitive, cost-effective way to deal with documents and simplify workflows. It offers a wide range of features, from generation to editing, eSignature professional services, and web form creating. The software can export your documents in many formats while maintaining highest protection and adhering to the maximum information safety standards.

Give DocHub a go and see just how easy your editing process can be.

welcome to dorman products installation video for exhaust gas temperature sensor bung replacement this installation is considered difficult and should take an hour to an hour and a half after removing the catalyst note this installation time does not include removing and reinstalling the catalyst with the catalyst and original egt sensor off the vehicle mark the area to be cut using the new bung mounting plate as a template using a cut-off wheel cut through the catalyst housing inside the marked lines leaving the corners attached for now with the four main cuts complete use a reciprocating saw to cut through two of the corners then pry the bung outward breaking through the remaining two corners to remove file any burrs from the edges of the cuts then use an abrasive disc to remove any corrosion from the area to be welded make any necessary adjustments to the bung mounting plate to conform to the contour of the catalyst housing using an appropriate welder for stainless steel thoroughly