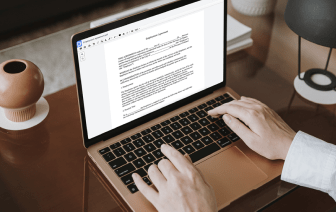

Not all formats, including pdf, are designed to be quickly edited. Even though a lot of tools can help us modify all document formats, no one has yet invented an actual all-size-fits-all solution.

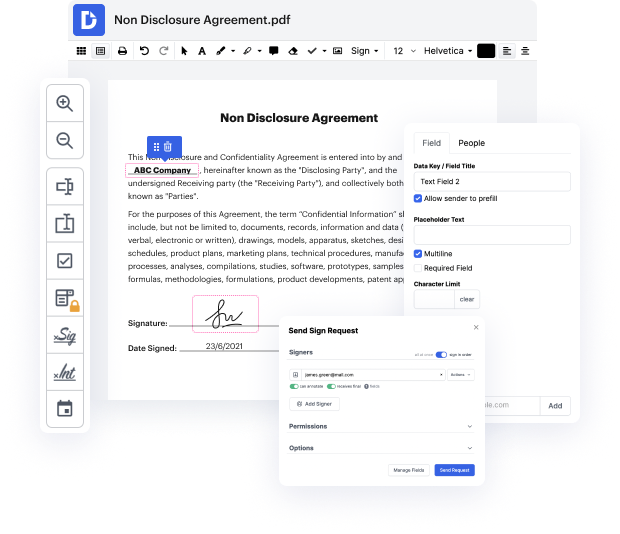

DocHub offers a simple and efficient solution for editing, managing, and storing paperwork in the most popular formats. You don't have to be a tech-knowledgeable person to tack secret in pdf or make other changes. DocHub is powerful enough to make the process simple for everyone.

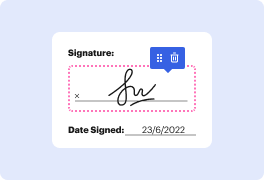

Our tool allows you to change and edit paperwork, send data back and forth, generate interactive documents for data gathering, encrypt and protect paperwork, and set up eSignature workflows. Moreover, you can also create templates from paperwork you use on a regular basis.

You’ll find plenty of other features inside DocHub, including integrations that let you link your pdf document to a wide array of business applications.

DocHub is a simple, fairly priced way to handle paperwork and simplify workflows. It offers a wide selection of capabilities, from generation to editing, eSignature services, and web form developing. The program can export your paperwork in many formats while maintaining highest security and following the highest data safety criteria.

Give DocHub a go and see just how simple your editing transaction can be.

welcome to technical studies in this video I will show you how to fit up slip on flanges on both ends of a pipe as for the code there are three different procedures for slip-on flange fitp in the first method the flange is overlapping the pipe the overlap shall be the thickness of the pipe or a minimum 6 mm in the second method the face of the pipe and the flunge are the same here you can see the flunge is beveled in the third method you can see the face of the pipe and the flunge are the same here the end of the pipe is beveled the first method is the most commonly used and we are going to do the fit up following this configuration make sure both ends of the pipes are square put the flunge in its position make small wedges from welding rod bits insert these wedges in the gap between the pipe and the flange as shown make sure the Gap is distributed equally around the pipe now adjust the gap between the face of the flange and the pipe tack weld on the top side check the squareness of th