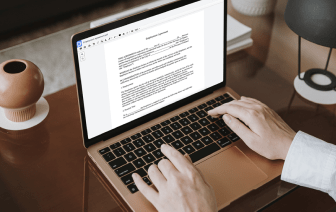

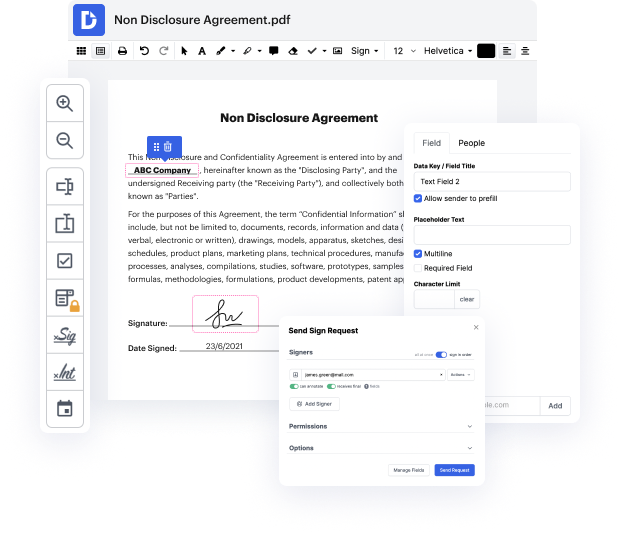

Many people find the process to strike size in CCF quite difficult, especially if they don't regularly work with paperwork. Nevertheless, today, you no longer need to suffer through long tutorials or spend hours waiting for the editing software to install. DocHub enables you to modify documents on their web browser without installing new applications. What's more, our powerful service provides a complete set of tools for comprehensive document management, unlike numerous other online tools. That’s right. You no longer have to export and import your forms so often - you can do it all in one go!

No matter what type of paperwork you need to modify, the process is simple. Make the most of our professional online service with DocHub!

In this video, weamp;#39;ll go through a step-by-step process for sizing control valves for compressible fluid using the ISA and IECamp;#39;s recommended procedure. For this example, weamp;#39;ll assume superheated steam is to be supplied to a process designed to operate at 250 psig, or 17.2 bar. The supply source is a header maintained at 500 psig, or 34.5 bar, and 500 degrees Fahrenheit, or 260 degrees Celsius. A NPS 6 or DN 150, standard schedule line from the steam main to the process is being planned. Note that a 6-inch standard schedule pipe has an inside diameter of 6.1 inches. Also, make the assumption that if the required valve size is less than NPS 6 or DN 150, it will be installed using concentric reducers. Now letamp;#39;s go through the process to determine the appropriate Fisher ED valve with a linear cage. The first step is to specify the variables required to size the valve. The desired valve design as a Class 300 globe valve with an assumed size of 4 inches and a l