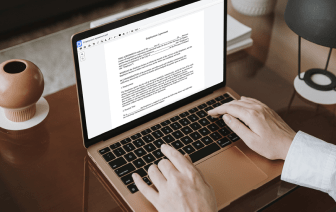

When you deal with diverse document types like Supply Inventory, you know how important precision and focus on detail are. This document type has its own specific structure, so it is crucial to save it with the formatting intact. For this reason, working with such documents might be a struggle for traditional text editing software: one incorrect action might ruin the format and take additional time to bring it back to normal.

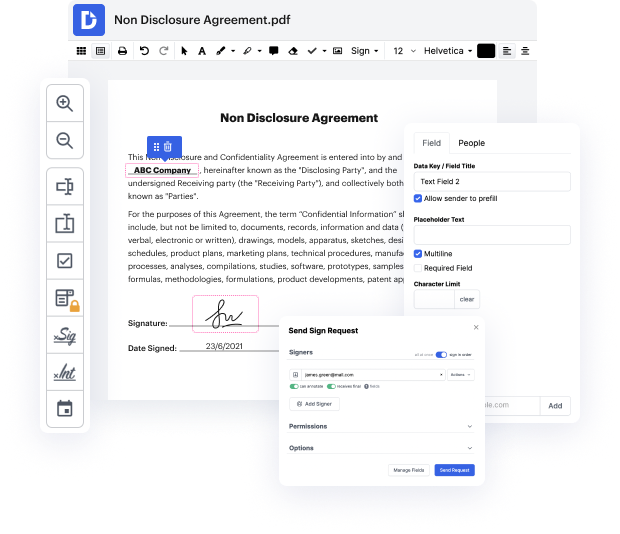

If you wish to set point in Supply Inventory without any confusion, DocHub is an ideal tool for this kind of tasks. Our online editing platform simplifies the process for any action you may want to do with Supply Inventory. The sleek interface design is proper for any user, whether that individual is used to working with this kind of software or has only opened it the very first time. Gain access to all modifying tools you require easily and save time on everyday editing activities. You just need a DocHub profile.

Discover how effortless papers editing can be irrespective of the document type on your hands. Gain access to all essential modifying features and enjoy streamlining your work on papers. Register your free account now and see immediate improvements in your editing experience.

mimax is one of the earliest automated replenishment methods which is now used across almost every piece of inventory software on the market its roots can originally be traced back to around the 19th century where it was developed as a visual method where you could physically see the amount of stock in a carefully sized bin the idea was that once stock docHubed a certain point this would trigger a replenishment which would bring the stock back to its maximum levels without the need for ever counting the exact amount of stock that it contained since then this fairly ancient method of automating variants has grown in popularity and is now used in various guises by almost every modern day company so how do these approaches compare to our trusty old system of a bin and a line well the approach is built on two conditions initially we start by tracking the current stock level which is typically the sum of stock on hand plus the sum of stock on order for every single sku then when the total s