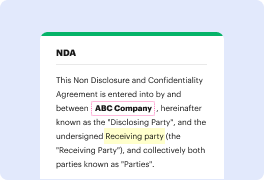

Not all formats, such as NB, are created to be quickly edited. Even though many capabilities will let us change all form formats, no one has yet created an actual all-size-fits-all tool.

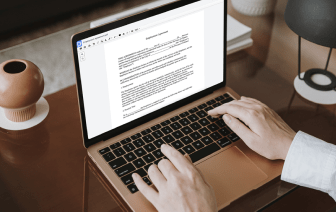

DocHub offers a easy and efficient tool for editing, managing, and storing paperwork in the most popular formats. You don't have to be a tech-knowledgeable person to rework type in NB or make other changes. DocHub is robust enough to make the process straightforward for everyone.

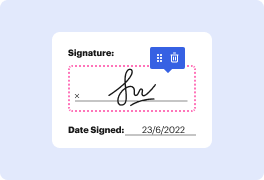

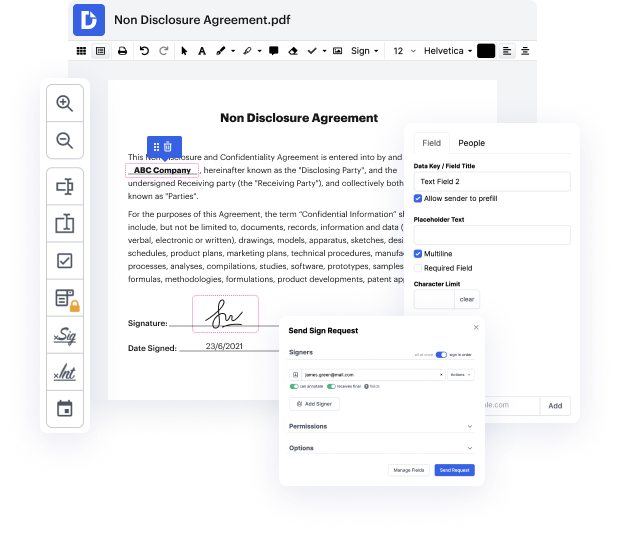

Our tool enables you to alter and tweak paperwork, send data back and forth, create interactive forms for data collection, encrypt and safeguard documents, and set up eSignature workflows. Additionally, you can also create templates from paperwork you utilize regularly.

You’ll locate a great deal of additional tools inside DocHub, including integrations that allow you to link your NB form to a variety productivity programs.

DocHub is a straightforward, fairly priced option to deal with paperwork and streamline workflows. It provides a wide range of tools, from generation to editing, eSignature professional services, and web form developing. The application can export your files in many formats while maintaining maximum protection and following the maximum data security standards.

Give DocHub a go and see just how straightforward your editing process can be.

Hi, Iamp;#39;m Mike from Siemens Digital Industries Software. Today, weamp;#39;ll show you some of the June 2024 enhancements for NX Model Based Part Manufacturing or MBPM. Itamp;#39;s one of several capabilities in NX and the Xcelerator platform that enables a true digital thread across the entire part manufacturing process. Weamp;#39;ll cover staged models, bill of process, work instructions, and the new NX Process Modeler application. Weamp;#39;ve already optimized the overall geometry of this bracket using a range of powerful AI and generative design tools. Check out our previous Whatamp;#39;s New video to see this functionality in action. Weamp;#39;ll put a link in the description. Now itamp;#39;s time to start preparing the design for manufacture. First step will be additive manufacturing, which means that weamp;#39;ll need to finish these smooth faces with CNC machining. These features are where the bracket interfaces with other components, so itamp;#39;s vital they me