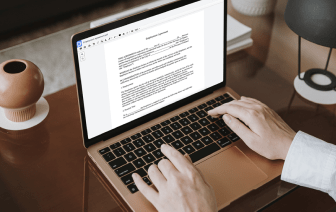

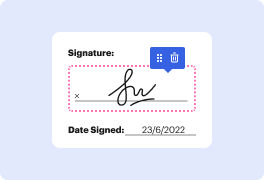

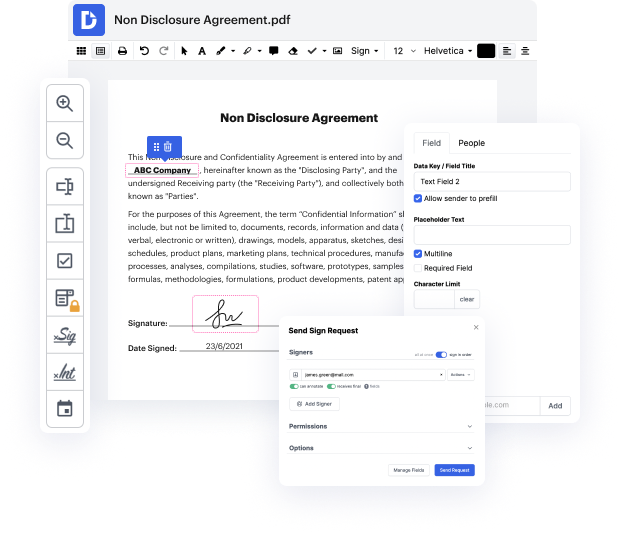

DocHub makes it fast and straightforward to rework result in OSHEET. No need to download any extra application – simply add your OSHEET to your profile, use the easy drag-and-drop interface, and quickly make edits. You can even work on your computer or mobile device to adjust your document online from any place. That's not all; DocHub is more than just an editor. It's an all-in-one document management platform with form creating, eSignature capabilities, and the option to let others fill in and eSign documents.

Each file you edit you can find in your Documents folder. Create folders and organize records for easier search and retrieval. In addition, DocHub ensures the security of all its users' data by complying with stringent protection standards.

In this video, we will demonstrate the steps to make a poor sheet metal component that can be unfolded in preparation for production. Open the poor sheet metal component. First, convert the entire model to Sheet Metal. By using the Split command, you can separate the top flange in this corner. It is possible to change the direction of the split. Create a split, in the same direction, on the underside as well. With the Bend command turn these sharp edges into bends. With the Junction command applied to the face, create a separation in this corner. If you now disable the junctions, and select the whole face of this sheet metal profile, you can pull it and extend it to overlap with the other sheet metal part, making a nicer and more seamless transition. On this other corner you can do it slightly differently: Select the Dissolve command to remove the Sheet Metal features. This allows you to use the Slice command. Using the Slice command select 3 points to create a split diagonally through