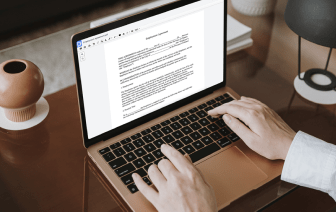

Not all formats, such as INFO, are created to be easily edited. Even though numerous features will let us modify all file formats, no one has yet invented an actual all-size-fits-all tool.

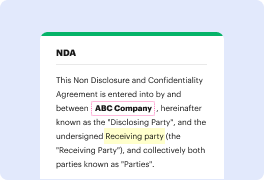

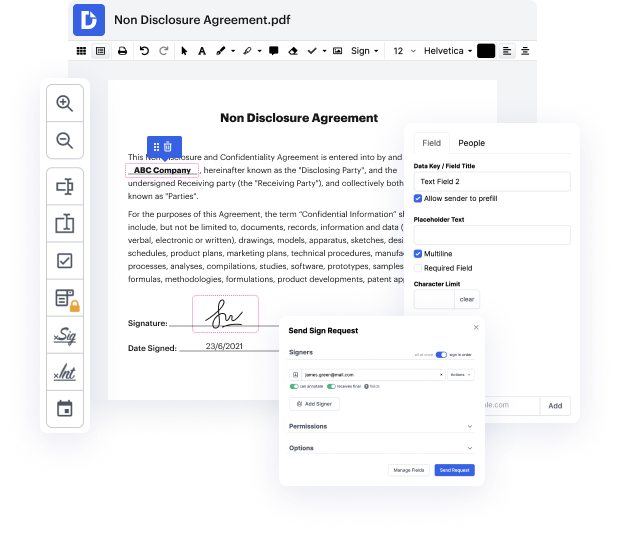

DocHub provides a straightforward and streamlined tool for editing, taking care of, and storing documents in the most popular formats. You don't have to be a technology-knowledgeable person to rework result in INFO or make other changes. DocHub is powerful enough to make the process simple for everyone.

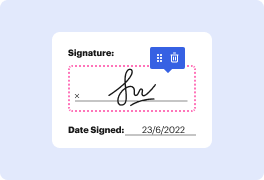

Our feature allows you to modify and edit documents, send data back and forth, generate dynamic forms for information collection, encrypt and protect forms, and set up eSignature workflows. In addition, you can also generate templates from documents you utilize regularly.

You’ll locate a great deal of other features inside DocHub, including integrations that allow you to link your INFO file to a wide array of productivity apps.

DocHub is a simple, cost-effective way to handle documents and streamline workflows. It offers a wide range of features, from creation to editing, eSignature professional services, and web document creating. The application can export your documents in multiple formats while maintaining highest security and adhering to the greatest information protection criteria.

Give DocHub a go and see just how simple your editing operation can be.

hi iamp;#39;m john iamp;#39;m responsible for a powertrain assembly line for quite some time weamp;#39;ve been discussing how we can gain control of our rework and repair processes todayamp;#39;s assembly processes are getting more and more complex a high number of variants parts and steps make error-free product assembly increasingly challenging what happens when an assembly step fails and the product needs repair or rework how can we get traceability of wrong and incomplete processes how can we know where the faults are which step is missing what is the right tool and what are the right parameters with atlas copcoamp;#39;s tools.8 we have gained traceability of our tightening process with clear insight and overview about our tightening quality but how can we implement a trustable rework process we checked this with our atlas capco assembly expert with their new software module toolsnet rework we now get full control of our repair and rework process we implemented toolsne