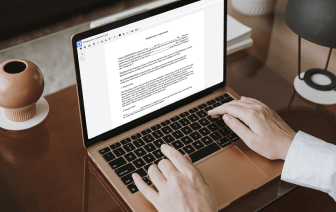

Not all formats, including DOCM, are created to be easily edited. Even though many tools will let us modify all form formats, no one has yet created an actual all-size-fits-all tool.

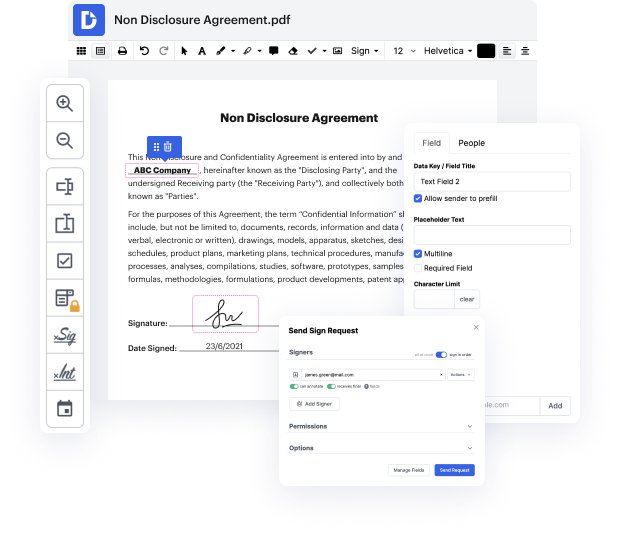

DocHub provides a easy and streamlined tool for editing, managing, and storing paperwork in the most popular formats. You don't have to be a technology-savvy user to put in construction in DOCM or make other tweaks. DocHub is powerful enough to make the process easy for everyone.

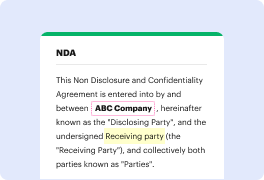

Our tool enables you to alter and edit paperwork, send data back and forth, generate interactive documents for information gathering, encrypt and safeguard forms, and set up eSignature workflows. Additionally, you can also create templates from paperwork you use regularly.

You’ll find a great deal of additional tools inside DocHub, including integrations that let you link your DOCM form to various business applications.

DocHub is a simple, fairly priced way to manage paperwork and simplify workflows. It provides a wide range of tools, from generation to editing, eSignature professional services, and web form creating. The application can export your files in multiple formats while maintaining maximum safety and adhering to the greatest information safety criteria.

Give DocHub a go and see just how easy your editing operation can be.

we decided to build a dock for the pond at the farm we figured this would be the best time to do it because the pond was low due to drought the dimensions of the dock are 14 feet long by 5 and a half feet wide the posts were made out of a 6x6 beam which had to be cut in half used in the [Applause] chainsaw [Applause] um we then dug two holes in the pond using the post hole digger attachment on our tractor we then slid the posts inside the ground we checked for level and then we pounded them in with a sledgehammer the rest of the dock was made out of 2x6 the main joists were cut to 16 inches on center we had a lot of troubles with this project including bowed and twisted boards which were probably in the barn for the past 30 years so and i had to get up on the dock and help straighten a lot of boards so steve was able to screw the boards down you will see this in the time lapse coming up in just a few minutes we had to use braces on the front part of the dock for extra support a