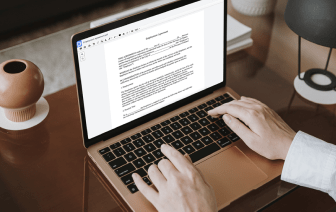

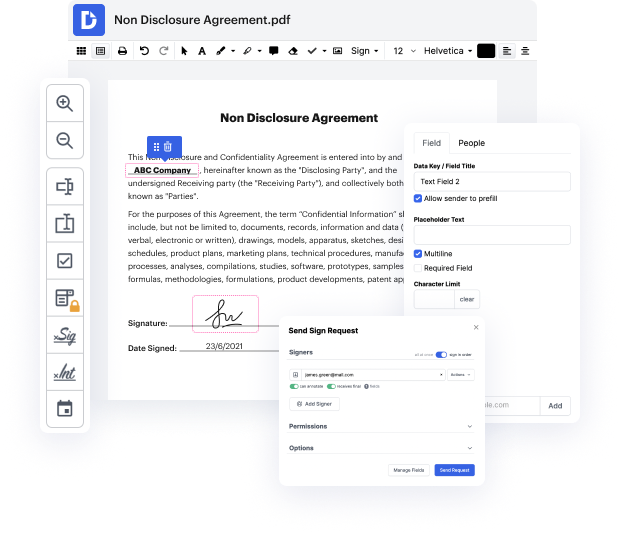

There are many document editing tools on the market, but only some are compatible with all file types. Some tools are, on the contrary, versatile yet burdensome to work with. DocHub provides the solution to these issues with its cloud-based editor. It offers rich functionalities that allow you to accomplish your document management tasks effectively. If you need to promptly Negate frame in OSHEET, DocHub is the perfect choice for you!

Our process is incredibly straightforward: you upload your OSHEET file to our editor → it automatically transforms it to an editable format → you make all necessary changes and professionally update it. You only need a couple of moments to get your paperwork done.

As soon as all alterations are applied, you can turn your paperwork into a reusable template. You simply need to go to our editor’s left-side Menu and click on Actions → Convert to Template. You’ll locate your paperwork stored in a separate folder in your Dashboard, saving you time the next time you need the same form. Try out DocHub today!

[Applause] so hey welcome to the shop im constantly getting asked about stick welding thin metal whether its sheet metal or thin walled tubing now is stick holding the right tool for the job is it even a good idea how thin can you go can i weld together the sharp edge of two box cutter razor blades stay tuned lets find out lets get on the same page about what we mean by thin material so im not talking about three millimeter or one eighth inch thick plate this is just fine for stick welding goes great no special treatment or anything in fact id recommend stick welding for this thickness of plate on up im talking about thinner than that now because i dont want to mislead anybody let me be clear that in these thinner materials mig welding and tig welding are better options than stick however i have had some good success stick welding 1 16 of an inch which is 16 gauge or one and a half millimeter thick plate using 60 13 electrodes let me show you how i do that and you may have seen