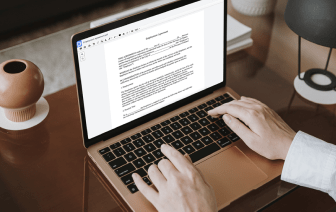

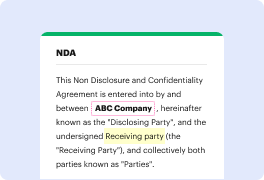

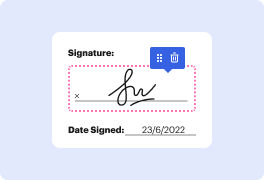

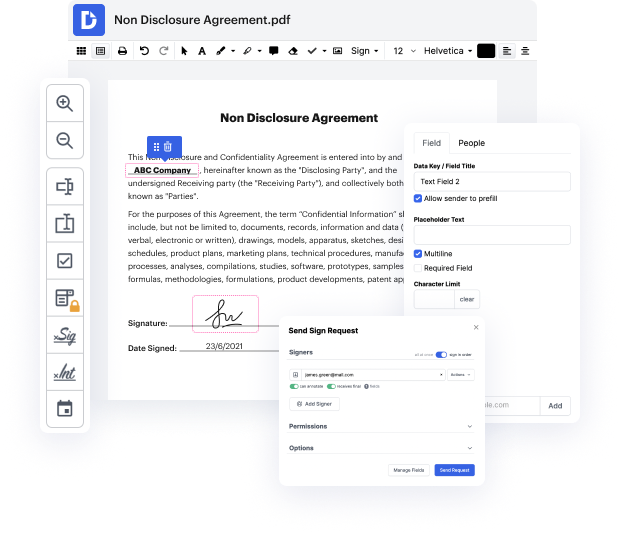

With DocHub, you can easily modify spot in scii from any place. Enjoy capabilities like drag and drop fields, editable textual content, images, and comments. You can collect eSignatures safely, include an extra layer of protection with an Encrypted Folder, and collaborate with teammates in real-time through your DocHub account. Make changes to your scii files online without downloading, scanning, printing or mailing anything.

You can find your edited record in the Documents folder of your account. Create, share, print out, or turn your file into a reusable template. With so many robust tools, it’s easy to enjoy trouble-free document editing and managing with DocHub.

Alright, that brings us to Tip #2, and Tip #2 is Skip the Grinding Step. Now by skipping the grinding step we actually skip at least half of the full processing time. If youll remember, I mentioned that the grinding step is actually several individual steps, and that really adds to the overall time it takes to fabricate an optic. So if we can skip that step we save a ton of time. How do we skip that step? Well, a lot of our optics off-the-shelf have a certain surface accuracy associated with them. Maybe youve heard the term quarter-wave or tenth-wave optic before. That has to do with the surface accuracy of the optic. Weve discovered we can use something called MRF technology here in our fabrication facility. And MRF technology is kind of a secondary polishing process, and it allows us to improve those polished surfaces into even better polished surfaces. So for instance, we could take something like a half-wave or quarter-wave surface and turn it into something like a tenth- or t