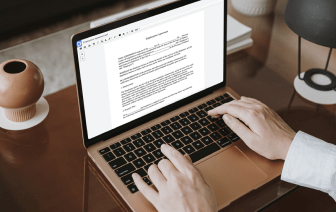

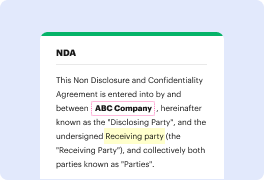

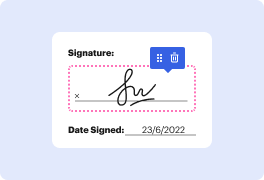

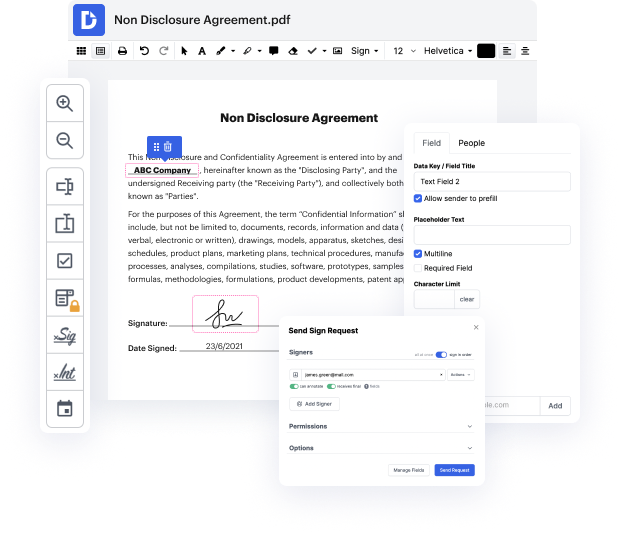

You no longer have to worry about how to modify dent in LWP. Our extensive solution guarantees simple and quick document management, enabling you to work on LWP documents in a few minutes instead of hours or days. Our service covers all the tools you need: merging, inserting fillable fields, signing documents legally, placing shapes, and so on. There’s no need to install extra software or bother with pricey programs demanding a powerful device. With only two clicks in your browser, you can access everything you need.

Start now and manage all different types of forms like a pro!

The Edmund Optics Barrington Fabrication Cell is used to create small lots of high quality optics in the form of purely custom parts, as well as modified off-the-shelf optics. Hi, Im Andrew Fisher, a Manufacturing Ramp;amp;D Engineer here at Edmund. Oftentimes, customers are looking to test out a design or prove out a concept before going into full scale production. In doing so, they need small quantities of optics very quickly, and here at Edmund, were equipped to get them there. Optical prototyping is all about getting the customer exactly what they need as fast as possible. We do this in several ways. First, we leverage the large inventory of off-the-shelf optics offered in our catalog. Second, we use automated versatile equipment to process these parts. And finally, and most importantly, we keep an open line of communication with the customer at all times during their prototyping process to make sure we get them the parts they need. From stitching interferometers to sub-aperture