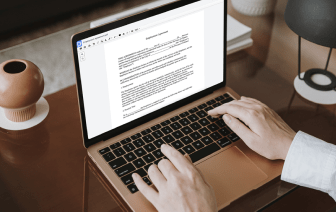

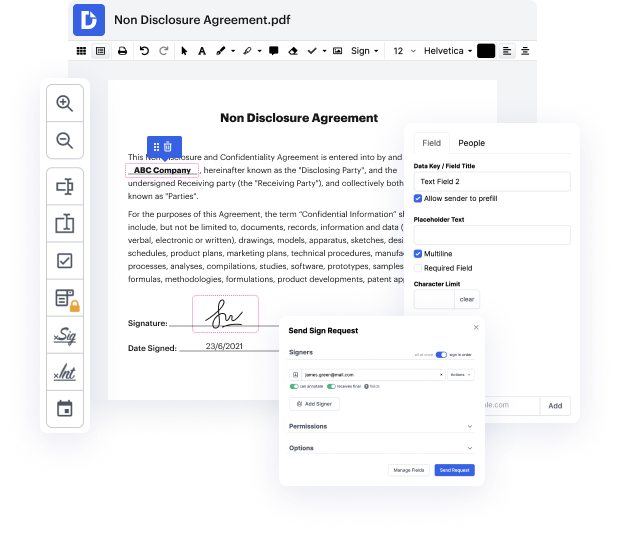

HWPML may not always be the easiest with which to work. Even though many editing features are out there, not all give a easy tool. We developed DocHub to make editing easy, no matter the file format. With DocHub, you can quickly and easily modify dent in HWPML. In addition to that, DocHub offers an array of other features such as form generation, automation and management, industry-compliant eSignature tools, and integrations.

DocHub also lets you save effort by producing form templates from paperwork that you use regularly. In addition to that, you can make the most of our numerous integrations that allow you to connect our editor to your most used applications effortlessly. Such a tool makes it quick and easy to deal with your files without any slowdowns.

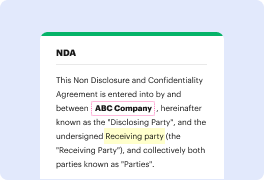

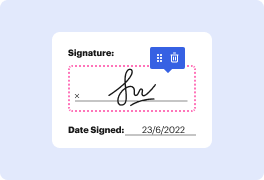

DocHub is a useful feature for personal and corporate use. Not only does it give a all-encompassing suite of features for form generation and editing, and eSignature implementation, but it also has an array of features that prove useful for creating multi-level and straightforward workflows. Anything added to our editor is kept safe in accordance with leading industry criteria that protect users' data.

Make DocHub your go-to option and simplify your form-driven workflows effortlessly!

hi everyone Marty here with another HSM works quick tip when finishing parts that have previously manufactured features like casts or additive parts probing cycles can shift and rotate the work coordinate system to more accurately match the part however there are some key components to successfully rotating the work coordinate system with a probing operation in the setup the X or Y axis should be aligned to the face I intend to probe the work coordinate system origin needs to be located at the center of any possible rotation locating pins or bores in a fixture plate like the one for this cast gearbox will ensure that the part is rotating around that specific point now to actually adjust the work coordinate system Iamp;#39;ll add a probe operation also flat-faced and change the probe type to why single surface angle clearance and over travel will define how far from the part the probe enters and how far past the expected location it travels these values posts directly into the probe ma