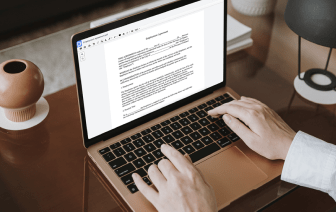

Flaws are present in every solution for editing every file type, and although you can find a wide variety of solutions out there, not all of them will suit your particular needs. DocHub makes it easier than ever to make and alter, and deal with documents - and not just in PDF format.

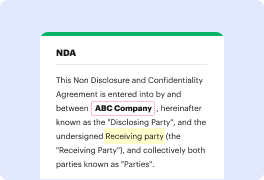

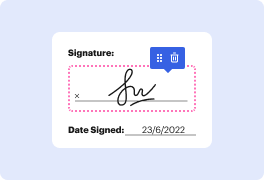

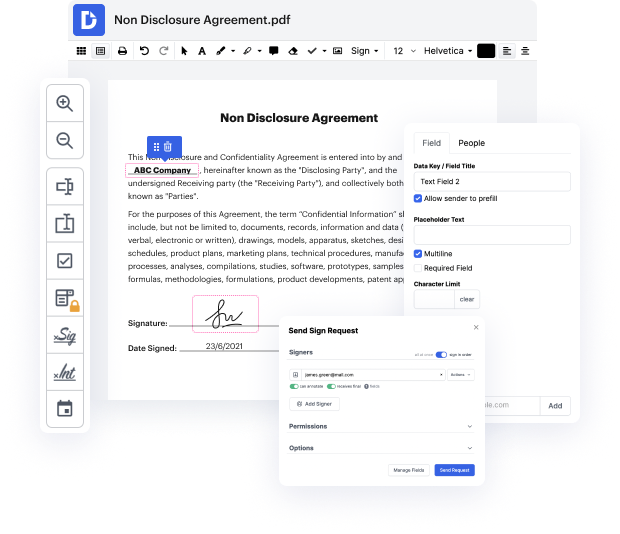

Every time you need to easily inlay trait in 600, DocHub has got you covered. You can effortlessly alter form components such as text and pictures, and structure. Customize, arrange, and encrypt documents, develop eSignature workflows, make fillable documents for stress-free information collection, and more. Our templates feature enables you to generate templates based on documents with which you often work.

Moreover, you can stay connected to your go-to productivity features and CRM platforms while handling your documents.

One of the most incredible things about leveraging DocHub is the option to handle form activities of any difficulty, regardless of whether you need a swift edit or more diligent editing. It includes an all-in-one form editor, website form builder, and workflow-centered features. Moreover, you can rest assured that your documents will be legally binding and comply with all safety frameworks.

Shave some time off your tasks by leveraging DocHub's features that make handling documents effortless.

you may recognize this part from our free five AIS Academy now this is the third part in the installment where we start really talking about those simultaneous tool paths we normally make this out of aluminum but today weamp;#39;re stepping it up a notch going to make it out of titanium and in this video not only am I going to show you the different techniques itamp;#39;s going to take to take this part from titanium from aluminum weamp;#39;re also going to give you the feeds and speeds for every single tool now remember guys if you want to learn how to program this part for yourself in aluminum be sure to check out our website where you can learn how to do this completely for free but as you can see this part is really tall so the things that we could get away with on aluminum weamp;#39;re not going to be able to get away with on titanium so some of our techniques are going to have to change a little bit and starting off weamp;#39;re going to have to go with a big