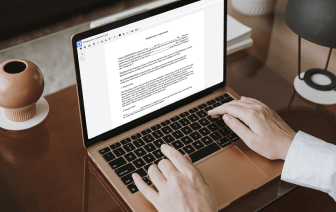

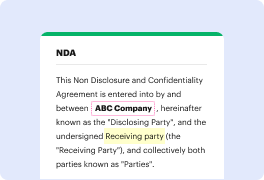

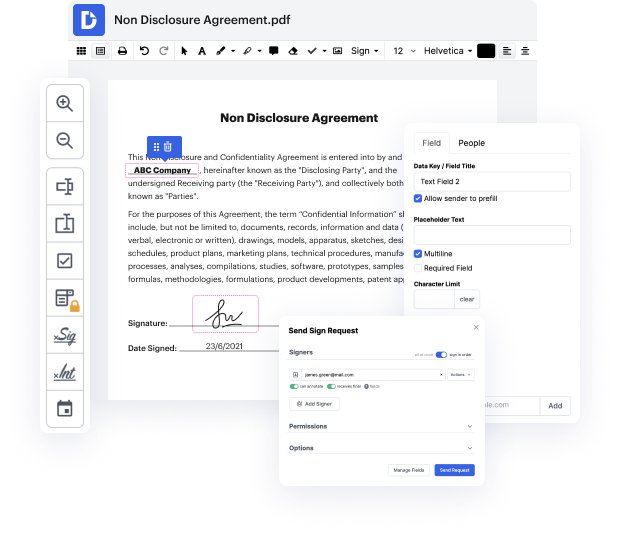

UOML may not always be the easiest with which to work. Even though many editing capabilities are available on the market, not all provide a simple tool. We created DocHub to make editing effortless, no matter the document format. With DocHub, you can quickly and effortlessly inlay TIN in UOML. On top of that, DocHub delivers a variety of other features such as document generation, automation and management, industry-compliant eSignature solutions, and integrations.

DocHub also helps you save time by creating document templates from documents that you use regularly. On top of that, you can benefit from our numerous integrations that allow you to connect our editor to your most utilized apps effortlessly. Such a tool makes it fast and simple to work with your files without any delays.

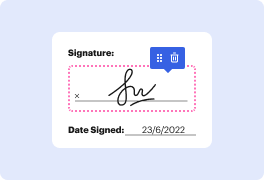

DocHub is a handy feature for individual and corporate use. Not only does it provide a extensive collection of capabilities for document generation and editing, and eSignature implementation, but it also has a variety of capabilities that prove useful for producing multi-level and straightforward workflows. Anything uploaded to our editor is stored secure in accordance with leading field criteria that protect users' data.

Make DocHub your go-to choice and simplify your document-based workflows effortlessly!

the last video we did on making a chair scrape we didnamp;#39;t have time to demonstrate the process of doing y inlay so in todayamp;#39;s video weamp;#39;re going to demonstrate why and lay techniques showing how to inlay Y into wood and some of the tools that are used during the process Iamp;#39;ve already inlaid the chest rape off line and weamp;#39;ll go weamp;#39;ll review it and look at the process that we went through when we speak of Y inlay and wood thereamp;#39;s three steps in the process the first step that weamp;#39;ll discuss and show some examples on is how to transfer the pattern onto the wood the second is what I refer to as stabbing in is where we actually use the tools to stab and open up the wood to a proper depth and opening to receive the ribbon wire the last step is trimming off the surplus wire thatamp;#39;s left above the wood level and bringing it back to a flush level so that the wire inlay is flush with the wood the weamp;#39;re after we cover each