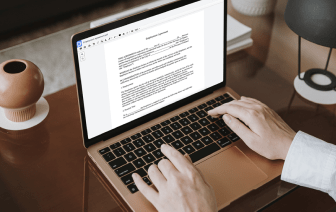

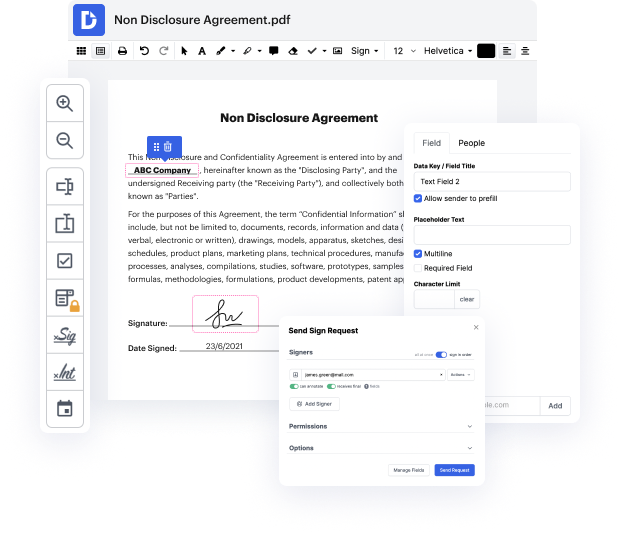

Disadvantages exist in every solution for editing every file type, and although you can use a wide variety of tools on the market, not all of them will fit your particular requirements. DocHub makes it easier than ever to make and modify, and handle documents - and not just in PDF format.

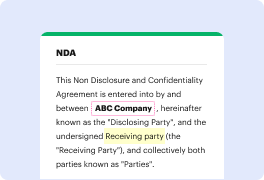

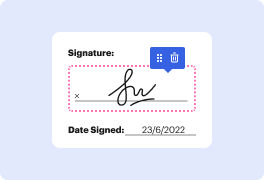

Every time you need to swiftly inlay style in PAP, DocHub has got you covered. You can easily alter form components including text and images, and layout. Personalize, organize, and encrypt documents, create eSignature workflows, make fillable forms for intuitive data collection, and more. Our templates option enables you to create templates based on documents with which you frequently work.

In addition, you can stay connected to your go-to productivity capabilities and CRM platforms while managing your documents.

One of the most remarkable things about utilizing DocHub is the ability to deal with form tasks of any difficulty, regardless of whether you require a swift tweak or more complex editing. It comes with an all-in-one form editor, website form builder, and workflow-centered capabilities. In addition, you can rest assured that your documents will be legally binding and adhere to all security protocols.

Cut some time off your tasks with the help of DocHub's features that make managing documents straightforward.

because we donamp;#39;t quite have one for every single room in the house I decided to make my wife yet another cutting board I really wanted this one to be a high quality and durable piece so I decided to make it a walnut engrain board and the slab of Walnut that I had was sporting some dry Rod so I figured Iamp;#39;d try to salvage as much material as I could and just work around it and then to Jazz it up a bit I figured a contrasting inlay would look pretty sharp also so Iamp;#39;ll work in another neat feature into the bottom which I think will make using the board even easier well here we go letamp;#39;s get started after getting the chunk of slab cut off the first step was to flatten one side over on the Joiner with that done I could then reference that edge on the table saw and begin to cut the slab into strips now with this piece being more than 2 in thick I had to take several pass while raising the blade between cuts this was to avoid overheating the blade burning