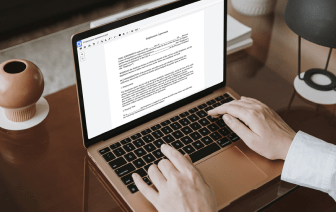

If you edit documents in various formats day-to-day, the universality of your document solution matters a lot. If your instruments work for only a few of the popular formats, you might find yourself switching between software windows to inlay shape in jpeg and manage other document formats. If you want to take away the headache of document editing, get a solution that can effortlessly handle any extension.

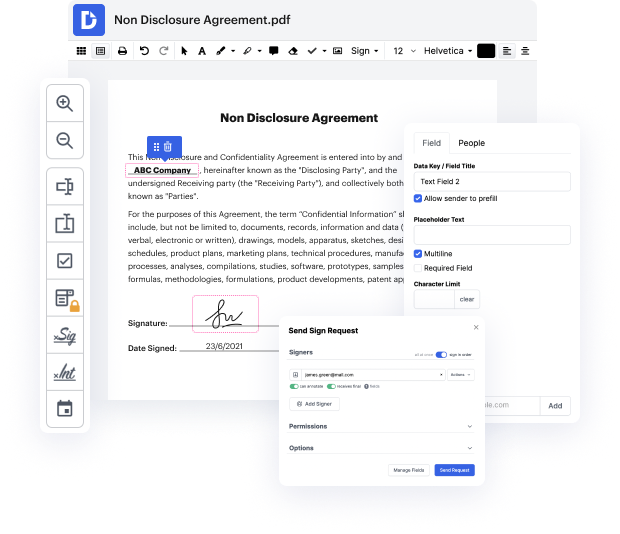

With DocHub, you do not need to focus on anything apart from actual document editing. You will not have to juggle programs to work with diverse formats. It can help you modify your jpeg as effortlessly as any other extension. Create jpeg documents, edit, and share them in a single online editing solution that saves you time and improves your productivity. All you need to do is sign up a free account at DocHub, which takes only a few minutes or so.

You will not need to become an editing multitasker with DocHub. Its functionality is enough for speedy papers editing, regardless of the format you want to revise. Start by creating a free account and see how easy document management can be having a tool designed particularly to suit your needs.

hi im dennis and in this video ill show you how i made this geisha figure on a 3d scroll out of four different types of natural unstained woods and carbon steel epoxy resin i originally planned to use the traditional cnc inlay technique but i ran into several technical issues which i solved with a new optimized prism technique for very precise inlays the inlay technique has been around for quite a while it is based on carving a pocket shape also called female into a board and then a mirrored protruding shape also called male that is usually carved out of wood with a contrasting color this mail piece is glued into the pocket and the excess wood is removed to reveal the shape a bit like those wooden puzzles for little kids but you can immediately see the problem at the corners when using a straight end mill you can cheat a bit with simple forms by rounding the corners but that wont work for sharp angles or lines that are thinner than the diameter of the bit as the bit just cant get