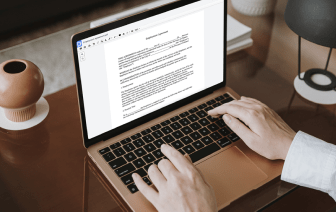

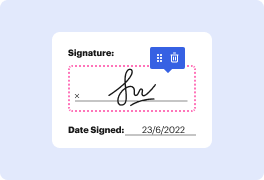

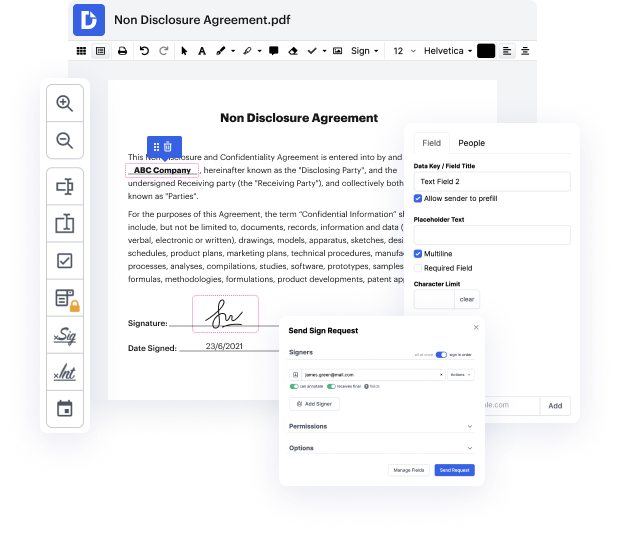

FDX may not always be the simplest with which to work. Even though many editing tools are available on the market, not all offer a easy solution. We developed DocHub to make editing easy, no matter the form format. With DocHub, you can quickly and easily inlay sample in FDX. In addition to that, DocHub offers an array of additional tools such as document generation, automation and management, field-compliant eSignature services, and integrations.

DocHub also helps you save effort by creating document templates from documents that you use frequently. In addition to that, you can make the most of our numerous integrations that enable you to connect our editor to your most utilized programs easily. Such a solution makes it fast and simple to work with your documents without any slowdowns.

DocHub is a helpful feature for personal and corporate use. Not only does it offer a comprehensive suite of tools for document generation and editing, and eSignature implementation, but it also has an array of tools that come in handy for producing multi-level and streamlined workflows. Anything imported to our editor is kept risk-free in accordance with leading industry criteria that shield users' data.

Make DocHub your go-to choice and streamline your document-based workflows easily!

[Applause] hey there everyone laser dave here again from trotec laser i have another laser hack to show you this laser hack will walk through the process of producing highly complex and detailed inlays with a laser system using a reverse engraving process with veneer woods to start i will show the traditional process of inlay as a baseline using maple wood and dark walnut wood veneer a vector file format is required i will use this lion design in this example the image will be black filled with a red cut outline to start the traditional laser inlay process first engrave the black and cut the red line of this file into the maple wood then wipe the surface with a damp cloth and remove it from the laser system and set it aside to cut the veneer convert the black engrave file to a cut line by removing the fill and adding a red outline then send that cut line to the laser using it to cut the thin walnut wood veneer after it is cut out remove it from the laser once completed the vene