Not all formats, such as 602, are created to be easily edited. Even though many features can help us tweak all file formats, no one has yet created an actual all-size-fits-all tool.

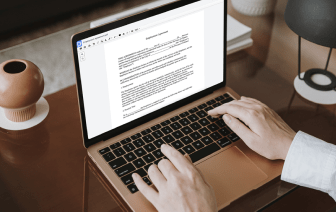

DocHub offers a simple and streamlined tool for editing, handling, and storing documents in the most widely used formats. You don't have to be a tech-knowledgeable user to inlay sample in 602 or make other tweaks. DocHub is robust enough to make the process easy for everyone.

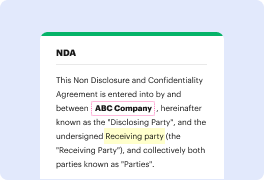

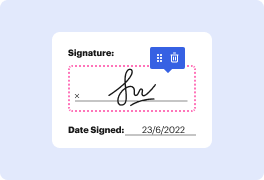

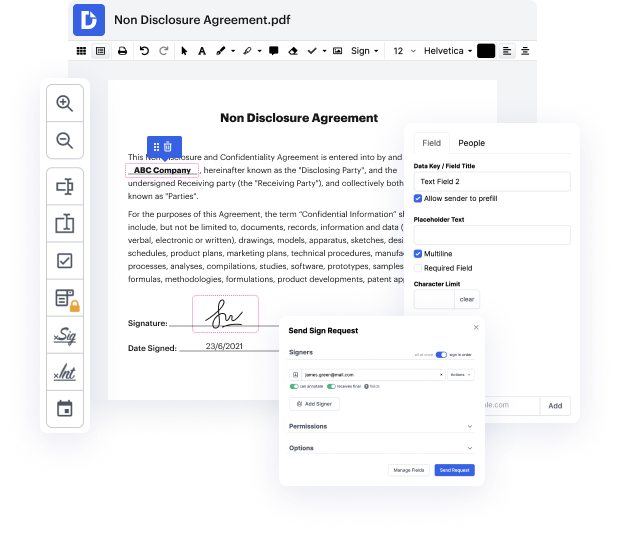

Our feature enables you to modify and edit documents, send data back and forth, generate dynamic documents for data gathering, encrypt and safeguard paperwork, and set up eSignature workflows. Additionally, you can also create templates from documents you use frequently.

You’ll find plenty of additional tools inside DocHub, including integrations that let you link your 602 file to a variety productivity apps.

DocHub is an intuitive, cost-effective option to deal with documents and simplify workflows. It provides a wide selection of capabilities, from creation to editing, eSignature professional services, and web document building. The application can export your paperwork in many formats while maintaining greatest protection and following the greatest data protection requirements.

Give DocHub a go and see just how easy your editing process can be.

[Applause] hey there everyone laser dave here again from trotec laser i have another laser hack to show you this laser hack will walk through the process of producing highly complex and detailed inlays with a laser system using a reverse engraving process with veneer woods to start i will show the traditional process of inlay as a baseline using maple wood and dark walnut wood veneer a vector file format is required i will use this lion design in this example the image will be black filled with a red cut outline to start the traditional laser inlay process first engrave the black and cut the red line of this file into the maple wood then wipe the surface with a damp cloth and remove it from the laser system and set it aside to cut the veneer convert the black engrave file to a cut line by removing the fill and adding a red outline then send that cut line to the laser using it to cut the thin walnut wood veneer after it is cut out remove it from the laser once completed the vene