Disadvantages are present in every solution for editing every file type, and despite the fact that you can use many solutions on the market, not all of them will fit your specific requirements. DocHub makes it much simpler than ever to make and alter, and deal with documents - and not just in PDF format.

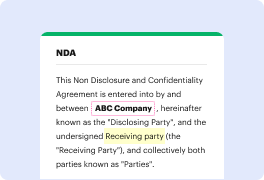

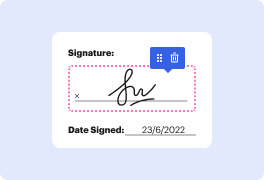

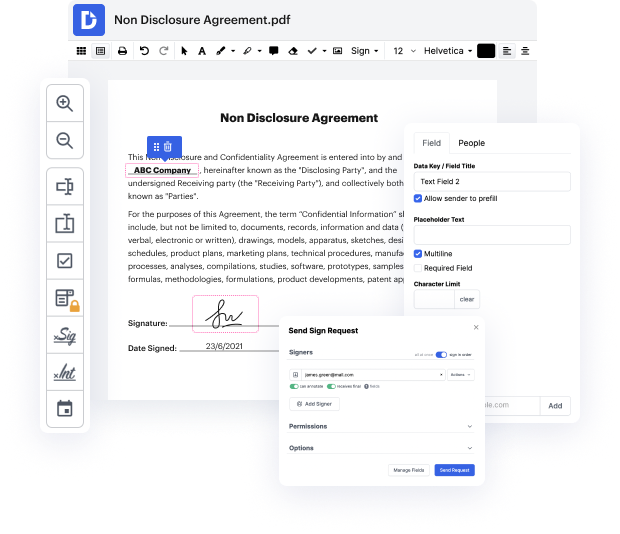

Every time you need to easily inlay redline in WPD, DocHub has got you covered. You can easily alter form components such as text and pictures, and structure. Personalize, organize, and encrypt files, develop eSignature workflows, make fillable documents for intuitive information gathering, and more. Our templates option enables you to generate templates based on documents with which you often work.

Additionally, you can stay connected to your go-to productivity features and CRM solutions while handling your files.

One of the most remarkable things about using DocHub is the ability to handle form tasks of any difficulty, regardless of whether you require a swift modify or more complex editing. It includes an all-in-one form editor, website form builder, and workflow-centered features. Additionally, you can be sure that your documents will be legally binding and adhere to all safety protocols.

Shave some time off your tasks with the help of DocHub's tools that make managing files straightforward.

in this tutorial weamp;#39;re going to look at the V inlay technique this is an alternative to making conventional uh pockets and inlays uh that uses a vbit tool rather than the usual uh n Mill or slot drill to to cut these shapes out now the reason this is docHub is that um by using a vbit tool to create um the inlays weamp;#39;re not limited by the normal radius problem that you get from a rotating tool so even in this artwork weamp;#39;ve got here which comes to Sharp points uh uh and quite quick sharp Corners here you um are able to get keep this detailed so if we was trying to just pocket this shape out firstly weamp;#39;d have to find an endmill which would fit all the way along the length of this pocket which would mean it would have to be extremely fine and secondly even if we could do that uh we would find that weamp;#39;d have radi on each of these Corners as the endmill canamp;#39;t get into the the corner to properly clear the material however with the V inlay Te