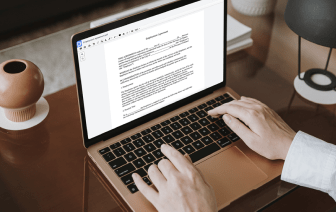

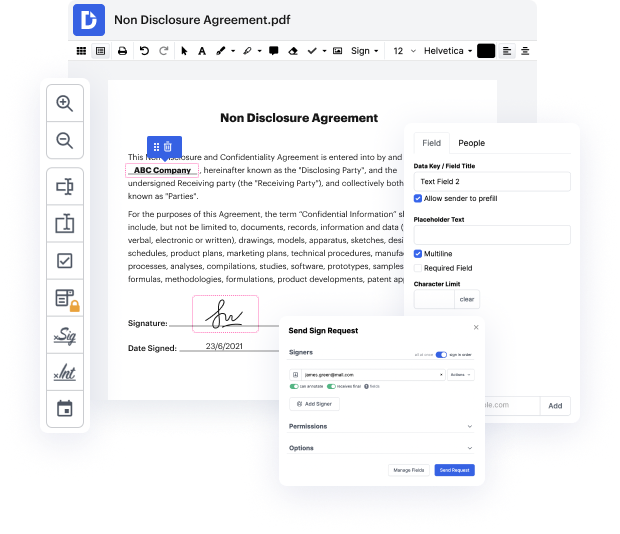

No matter how complex and challenging to change your files are, DocHub offers a simple way to modify them. You can modify any part in your XPS with no extra resources. Whether you need to tweak a single component or the whole form, you can rely on our powerful solution for quick and quality results.

In addition, it makes certain that the final form is always ready to use so that you’ll be able to get on with your projects without any slowdowns. Our all-encompassing set of capabilities also comes with advanced productivity features and a library of templates, allowing you to make best use of your workflows without the need of wasting time on recurring operations. In addition, you can access your documents from any device and incorporate DocHub with other apps.

DocHub can handle any of your form management operations. With a great deal of capabilities, you can create and export paperwork however you want. Everything you export to DocHub’s editor will be stored safely as much time as you need, with strict safety and information protection frameworks in place.

Try out DocHub today and make managing your documents simpler!

the last video we did on making a chair scrape we didnamp;#39;t have time to demonstrate the process of doing y inlay so in todayamp;#39;s video weamp;#39;re going to demonstrate why and lay techniques showing how to inlay Y into wood and some of the tools that are used during the process Iamp;#39;ve already inlaid the chest rape off line and weamp;#39;ll go weamp;#39;ll review it and look at the process that we went through when we speak of Y inlay and wood thereamp;#39;s three steps in the process the first step that weamp;#39;ll discuss and show some examples on is how to transfer the pattern onto the wood the second is what I refer to as stabbing in is where we actually use the tools to stab and open up the wood to a proper depth and opening to receive the ribbon wire the last step is trimming off the surplus wire thatamp;#39;s left above the wood level and bringing it back to a flush level so that the wire inlay is flush with the wood the weamp;#39;re after we cover each