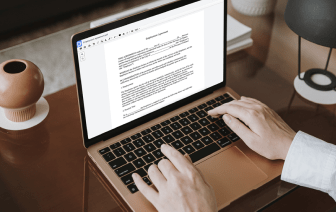

Flaws exist in every solution for editing every document type, and even though you can use a lot of solutions out there, not all of them will suit your specific requirements. DocHub makes it much simpler than ever to make and alter, and manage documents - and not just in PDF format.

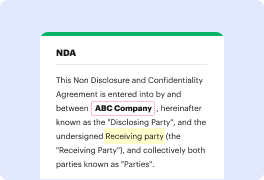

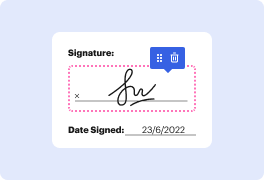

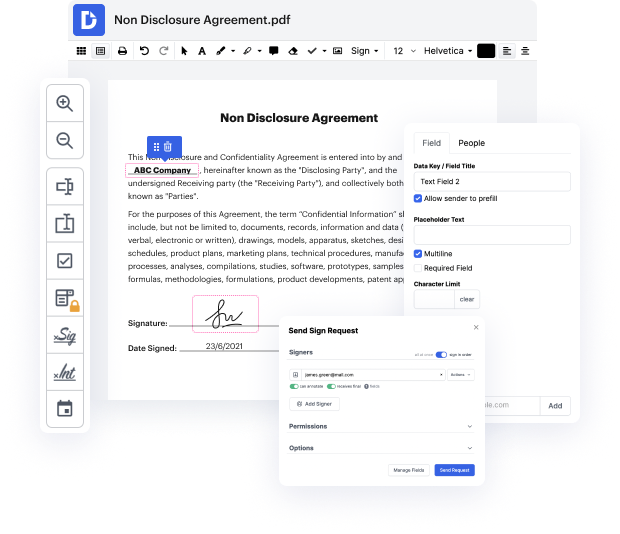

Every time you need to swiftly inlay margin in cgi, DocHub has got you covered. You can easily modify document elements including text and images, and layout. Personalize, organize, and encrypt files, develop eSignature workflows, make fillable forms for intuitive data collection, etc. Our templates feature enables you to generate templates based on documents with which you often work.

In addition, you can stay connected to your go-to productivity features and CRM solutions while managing your files.

One of the most extraordinary things about leveraging DocHub is the ability to manage document tasks of any difficulty, regardless of whether you require a quick tweak or more complex editing. It comes with an all-in-one document editor, website form builder, and workflow-centered features. In addition, you can be sure that your documents will be legally binding and abide by all protection protocols.

Shave some time off your projects with the help of DocHub's tools that make managing files easy.

all right so cad/cam inlays now letamp;#39;s start with inlays so what do we know about the difference between an inlay and an onlay right so on lay youamp;#39;re covering thing that is on top of the cusp and then inlay is sort of in between right so weamp;#39;ll start with inlay which if you kind of look at it itamp;#39;s kind of like just a mo deep rep or a class two preparation right where you have a large restoration that instead of using composite you rather use a material thatamp;#39;s all kind of polymerize or cured in one whole unit because if you look at our direct composite what do we have to do when we fill in mo d letamp;#39;s say with composite you got to layer it right and why do we have to do that incrementally whatamp;#39;s the reason behind that polymerization shrinkage of the composite so based on our operative class whatamp;#39;s the recommended increment that we build this up in about two millimeters right max okay so weamp;#39;re going to layer or add on t