Document generation and approval certainly are a central focus for each firm. Whether dealing with sizeable bulks of files or a particular agreement, you need to stay at the top of your productivity. Getting a excellent online platform that tackles your most frequentl papers generation and approval difficulties might result in quite a lot of work. Many online apps offer just a restricted list of editing and eSignature capabilities, some of which could possibly be useful to handle CWK format. A platform that deals with any format and task will be a outstanding option when deciding on software.

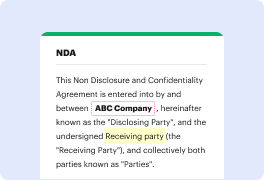

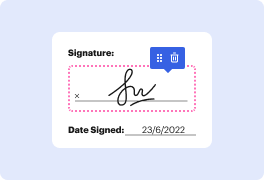

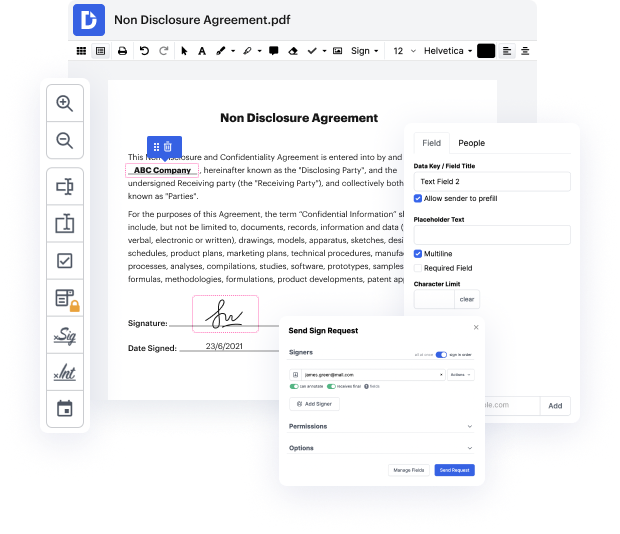

Get document managing and generation to another level of simplicity and excellence without opting for an awkward user interface or costly subscription plan. DocHub gives you instruments and features to deal effectively with all document types, including CWK, and carry out tasks of any difficulty. Edit, arrange, that will create reusable fillable forms without effort. Get total freedom and flexibility to inlay logo in CWK anytime and securely store all of your complete documents in your account or one of several possible integrated cloud storage apps.

DocHub provides loss-free editing, signature collection, and CWK managing on the expert level. You don’t need to go through tedious guides and spend hours and hours finding out the application. Make top-tier safe document editing a typical practice for the everyday workflows.

- [Voiceover] Marquetry, or wood mosaics, are made by arranging hundreds of small separately cut pieces of wood into an intricate design. The process for making marquetry began when I craftsman drew, or more often traced, a design on paper. This drawing was then secured to a sheet of heavy brown paper. Following the lines of the drawing, the craftsman perforated the pattern. Although now made with a device similar to a sewing machine, during the 18th century, thousands of holes had to be laboriously punched by hand with a needle. This heavy sheet, called the pounce pattern, was laid on top of a sheet of white paper. The craftsman then rubbed graphite over the surface of the perforated pattern to transfer the design to the bottom sheet. The design could be reproduced several times using this method. The wood was then sliced into thin sheets called veneers. In the 1700s, skilled artisans using a cumbersome hand-held saw, could cut veneer as thin as one millimeter. Elaborate marquetry de