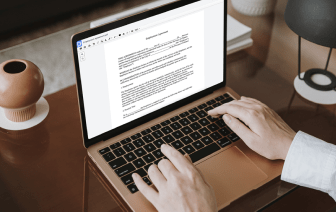

Picking out the ideal document management platform for your firm might be time-consuming. You have to analyze all nuances of the software you are thinking about, evaluate price plans, and remain aware with protection standards. Arguably, the opportunity to work with all formats, including AWW, is crucial in considering a platform. DocHub has an extensive list of features and tools to successfully deal with tasks of any complexity and handle AWW formatting. Register a DocHub account, set up your workspace, and begin working with your documents.

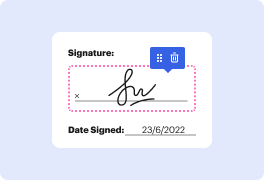

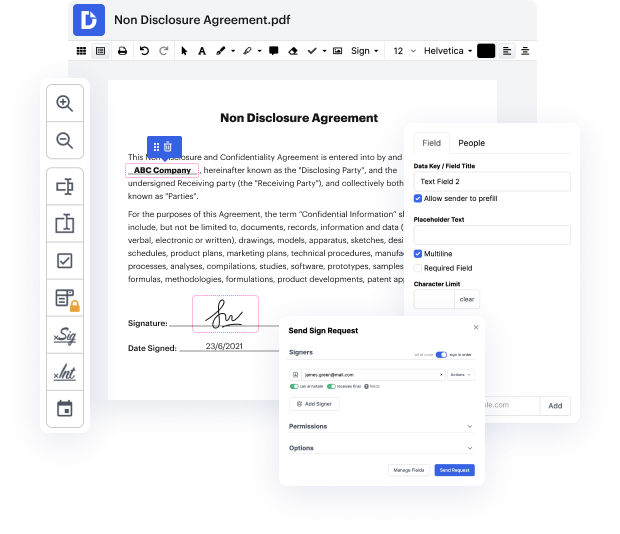

DocHub is a extensive all-in-one platform that allows you to change your documents, eSign them, and make reusable Templates for the most frequently used forms. It offers an intuitive user interface and the opportunity to deal with your contracts and agreements in AWW formatting in a simplified way. You don’t need to worry about studying numerous tutorials and feeling stressed because the app is way too complex. inlay logo in AWW, assign fillable fields to chosen recipients and collect signatures easily. DocHub is all about powerful features for specialists of all backgrounds and needs.

Improve your document generation and approval procedures with DocHub right now. Benefit from all of this using a free trial version and upgrade your account when you are all set. Edit your documents, make forms, and learn everything you can do with DocHub.

today there you going and welcome to my workshop so today were going to do something a little bit complex what were actually going to do is were going to make an inlay with a laser so that means were gonna actually cut the pieces out like this and then etch out a negative in a piece of oak and lay it in machining often see if we can make a perfect inlay you come in you can make inlays with it CNC routers quite successfully but you cant get my sharp corners with it really not with an end mill so we do it with a laser so what we need to do is find out the settings of the laser to be able to first of all cut this out perfectly and then etch out a negative in oak and this material is [Music] one-point-five just a little bit over 1.5 millimeters which is 61 fell alright for those of you who work in thousandths of an inch or inches so we need to work out with a test subject a test part how much power speed we need to be able to machine that out of oak and cut it out of this this is you