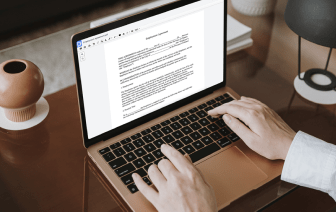

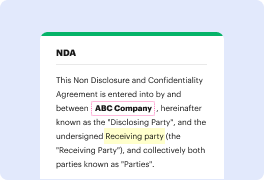

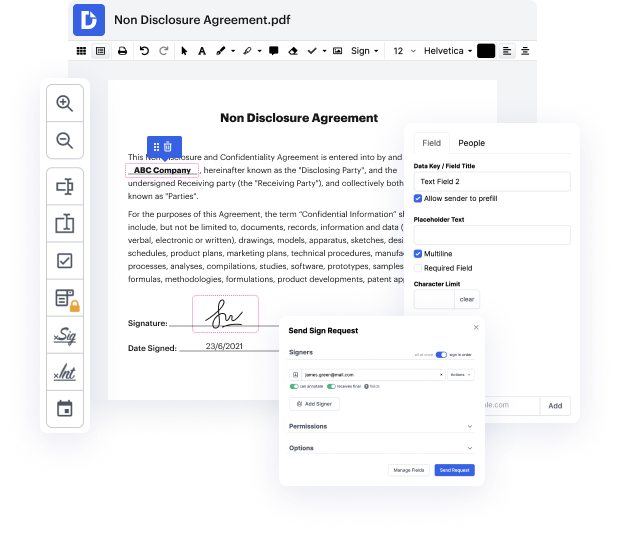

xht may not always be the simplest with which to work. Even though many editing features are available on the market, not all give a straightforward tool. We developed DocHub to make editing easy, no matter the document format. With DocHub, you can quickly and effortlessly inlay identification in xht. On top of that, DocHub gives an array of additional tools including document creation, automation and management, sector-compliant eSignature solutions, and integrations.

DocHub also helps you save time by producing document templates from paperwork that you utilize frequently. On top of that, you can benefit from our a wide range of integrations that enable you to connect our editor to your most utilized apps easily. Such a tool makes it quick and easy to deal with your files without any delays.

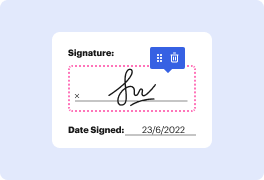

DocHub is a handy tool for personal and corporate use. Not only does it give a extensive suite of capabilities for document generation and editing, and eSignature implementation, but it also has an array of features that come in handy for creating multi-level and streamlined workflows. Anything added to our editor is kept risk-free in accordance with major industry criteria that protect users' data.

Make DocHub your go-to choice and streamline your document-driven workflows easily!

hi iamp;#39;m dennis and in this video iamp;#39;ll show you how i made this geisha figure on a 3d scroll out of four different types of natural unstained woods and carbon steel epoxy resin i originally planned to use the traditional cnc inlay technique but i ran into several technical issues which i solved with a new optimized prism technique for very precise inlays the inlay technique has been around for quite a while it is based on carving a pocket shape also called female into a board and then a mirrored protruding shape also called male that is usually carved out of wood with a contrasting color this mail piece is glued into the pocket and the excess wood is removed to reveal the shape a bit like those wooden puzzles for little kids but you can immediately see the problem at the corners when using a straight end mill you can cheat a bit with simple forms by rounding the corners but that wonamp;#39;t work for sharp angles or lines that are thinner than the diameter of the bit as