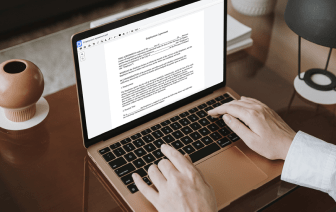

Not all formats, including AWW, are designed to be quickly edited. Even though many capabilities can help us tweak all document formats, no one has yet invented an actual all-size-fits-all solution.

DocHub provides a simple and streamlined solution for editing, managing, and storing paperwork in the most popular formats. You don't have to be a technology-savvy user to inlay heading in AWW or make other tweaks. DocHub is powerful enough to make the process simple for everyone.

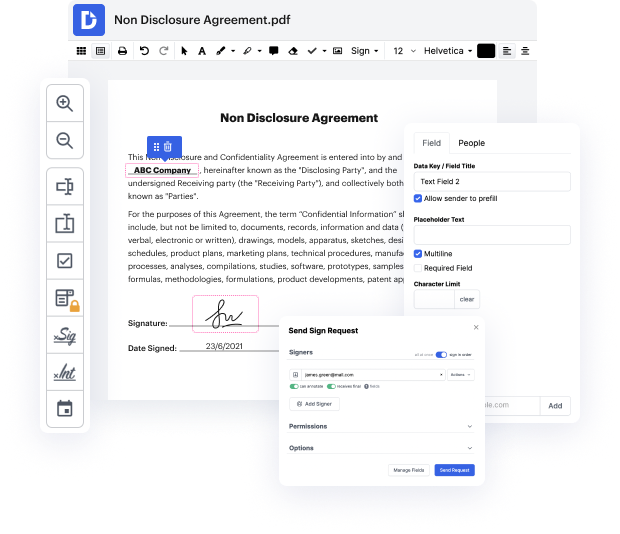

Our tool enables you to modify and edit paperwork, send data back and forth, generate interactive forms for information collection, encrypt and shield forms, and set up eSignature workflows. Additionally, you can also create templates from paperwork you use on a regular basis.

You’ll find plenty of other features inside DocHub, such as integrations that allow you to link your AWW document to different productivity programs.

DocHub is a simple, fairly priced option to deal with paperwork and streamline workflows. It offers a wide range of features, from creation to editing, eSignature providers, and web form creating. The application can export your documents in multiple formats while maintaining maximum safety and following the maximum information protection criteria.

Give DocHub a go and see just how simple your editing transaction can be.

[Applause] in this video Iamp;#39;m going to explain the be carved technique for creating wouldnamp;#39;t in lace I will also demonstrate this method by making a coaster with a butterfly in light v carp inlays have two big advantages the first is you can create complex inlays with sharp corners and multiple parts with a single piece of wood for easy assembly second because of the wedge-shaped of the inlay they can tolerate gluing alignment and machining errors quite well even in thin pieces of wood if you would like to skip the next section explaining the background on how we carve inlays work jump to the 9 minutes 30 seconds mark in the video to get to the CAD cam tutorial if you want to skip all the way to the machining section jump to the 22 minutes 40 seconds mark first Iamp;#39;m gonna go through some theory of V carve inlays and the basics of how to machine them so in this diagram the blue arrow represents the V bit and the brown rectangle represents the materi