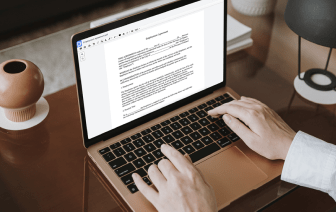

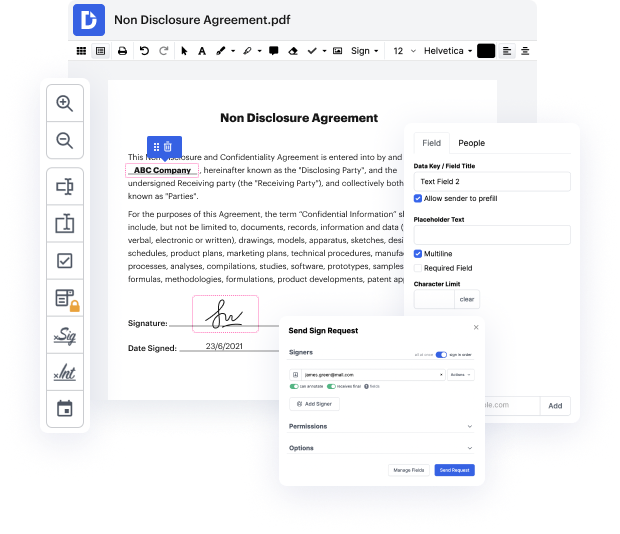

602 may not always be the easiest with which to work. Even though many editing tools are out there, not all give a straightforward solution. We designed DocHub to make editing effortless, no matter the document format. With DocHub, you can quickly and effortlessly inlay heading in 602. Additionally, DocHub gives a variety of additional tools including document generation, automation and management, field-compliant eSignature solutions, and integrations.

DocHub also helps you save effort by producing document templates from paperwork that you utilize frequently. Additionally, you can take advantage of our a wide range of integrations that enable you to connect our editor to your most utilized apps effortlessly. Such a solution makes it fast and simple to work with your documents without any delays.

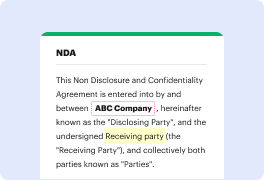

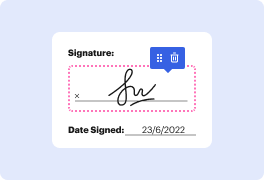

DocHub is a useful feature for personal and corporate use. Not only does it give a extensive collection of features for document generation and editing, and eSignature implementation, but it also has a variety of tools that come in handy for developing multi-level and streamlined workflows. Anything uploaded to our editor is stored secure in accordance with major field requirements that safeguard users' data.

Make DocHub your go-to option and streamline your document-centered workflows effortlessly!

itamp;#39;s time to get back to the coffee pod project weamp;#39;re going to be cutting the backer board that weamp;#39;re going to inlay pieces into starting out with a quinch down cut bit to go through and remove the majority of the waist throughout all of these Pockets down cut bits leave a perfectly clean top surface of the material which is exactly what we want to see here for the inlay we got everything all cut out and cleared out with that so weamp;#39;ll switch out for a E8 in down cut bit to go through and do all of the fine details just clean up those edges where weamp;#39;re going to inlay those pieces it gets all of the areas that the Quin bit will not be able to fit into and gets those all cleaned out and weamp;#39;ll switch out for a/ Quin compression bit and this bit has a upcut portion and down cut portion of the bit which means it leaves a nice clean surface on the top and bottom of the material you just have to make sure that your first pass is below the upcut p