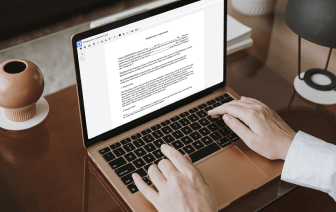

Not all formats, including ACL, are developed to be quickly edited. Even though a lot of features can help us edit all file formats, no one has yet invented an actual all-size-fits-all solution.

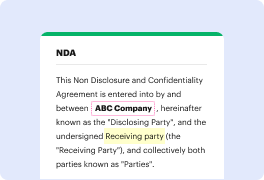

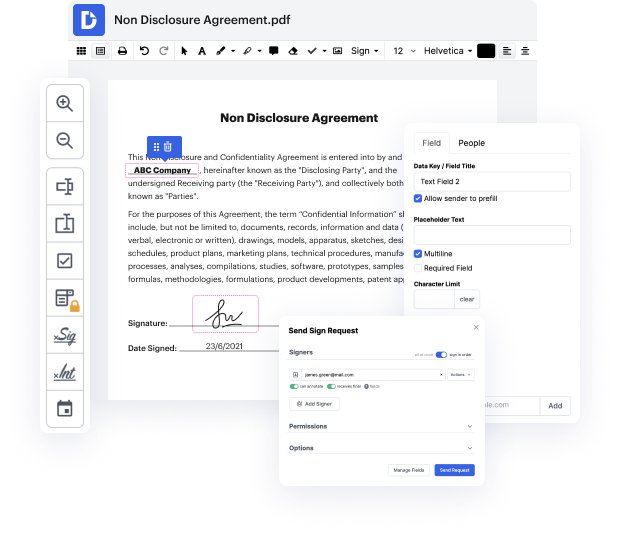

DocHub offers a easy and streamlined solution for editing, managing, and storing papers in the most popular formats. You don't have to be a technology-knowledgeable user to inlay first name in ACL or make other changes. DocHub is powerful enough to make the process straightforward for everyone.

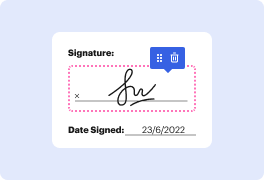

Our tool allows you to modify and edit papers, send data back and forth, generate interactive forms for information collection, encrypt and shield paperwork, and set up eSignature workflows. Additionally, you can also generate templates from papers you use on a regular basis.

You’ll find a great deal of other functionality inside DocHub, such as integrations that let you link your ACL file to different business applications.

DocHub is a straightforward, cost-effective way to handle papers and streamline workflows. It offers a wide array of capabilities, from generation to editing, eSignature providers, and web document building. The software can export your files in many formats while maintaining highest protection and adhering to the maximum information safety requirements.

Give DocHub a go and see just how straightforward your editing operation can be.

have you been wanting to learn how to create inlays with your CNC router then youamp;#39;ve come to the right video because I am going to teach you exactly how to do inlays from the beginning to the very end and Iamp;#39;m going to take you step by step through the entire process and by the time youamp;#39;re done you will watch your own amazing inlay CNC router project come to life just like youamp;#39;re watching here youamp;#39;re going to learn actually how easy it is to create an inlay and how perfect you can get them so long as you follow a few simple specific steps which you are going to get in this video what Iamp;#39;m going to do with you is we are going to find the design in this case the feather and then weamp;#39;re going to actually design up the inlay for the insert and for the base piece and then weamp;#39;re going to run out tool paths and then you and I are going to run it out on our longmill CNC router Iamp;#39;m going to teach you how to take two raw pieces