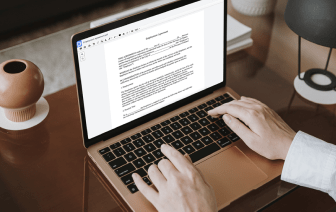

Flaws are present in every tool for editing every document type, and despite the fact that you can find a lot of solutions out there, not all of them will suit your specific requirements. DocHub makes it much simpler than ever to make and alter, and manage documents - and not just in PDF format.

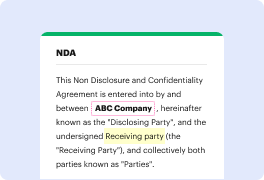

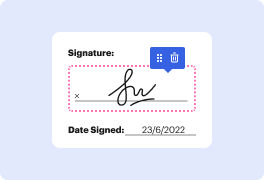

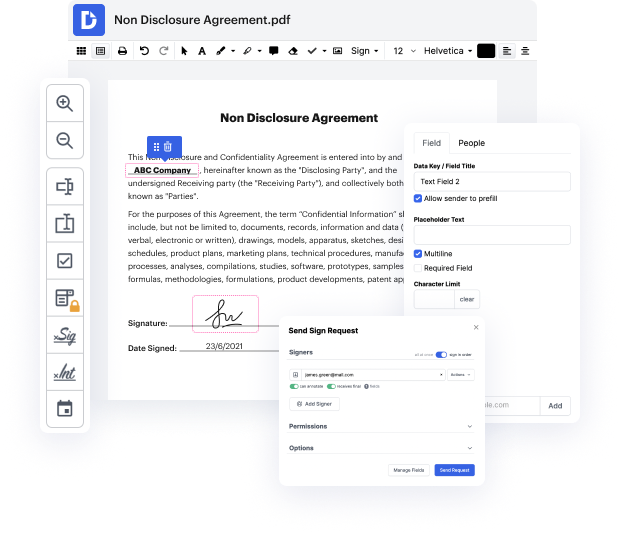

Every time you need to easily inlay company in xhtml, DocHub has got you covered. You can quickly alter document components including text and images, and structure. Personalize, arrange, and encrypt files, build eSignature workflows, make fillable forms for stress-free data gathering, and more. Our templates feature allows you to generate templates based on documents with which you often work.

Moreover, you can stay connected to your go-to productivity capabilities and CRM platforms while managing your files.

One of the most incredible things about utilizing DocHub is the ability to manage document activities of any complexity, regardless of whether you require a fast modify or more complex editing. It includes an all-in-one document editor, website document builder, and workflow-centered capabilities. Moreover, you can be certain that your documents will be legally binding and comply with all protection protocols.

Cut some time off your tasks with the help of DocHub's features that make handling files effortless.

[Applause] hey there everyone laser dave here again from trotec laser i have another laser hack to show you this laser hack will walk through the process of producing highly complex and detailed inlays with a laser system using a reverse engraving process with veneer woods to start i will show the traditional process of inlay as a baseline using maple wood and dark walnut wood veneer a vector file format is required i will use this lion design in this example the image will be black filled with a red cut outline to start the traditional laser inlay process first engrave the black and cut the red line of this file into the maple wood then wipe the surface with a damp cloth and remove it from the laser system and set it aside to cut the veneer convert the black engrave file to a cut line by removing the fill and adding a red outline then send that cut line to the laser using it to cut the thin walnut wood veneer after it is cut out remove it from the laser once completed the vene