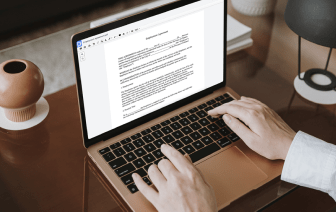

Flaws are present in every solution for editing every document type, and despite the fact that you can use many solutions out there, not all of them will suit your specific requirements. DocHub makes it easier than ever to make and alter, and handle paperwork - and not just in PDF format.

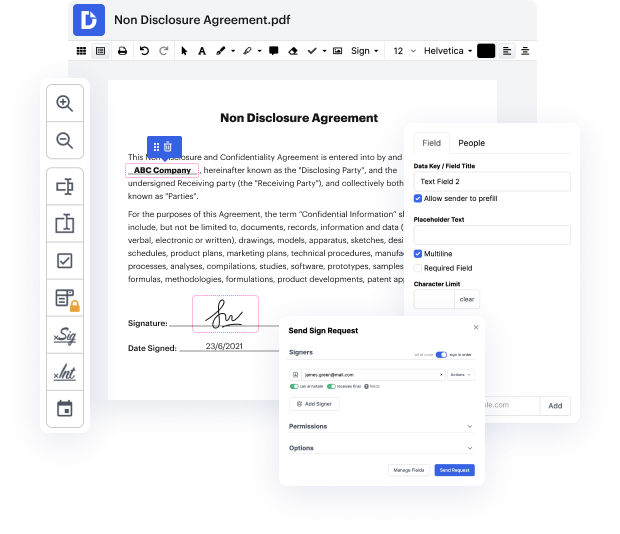

Every time you need to swiftly inlay banner in ASC, DocHub has got you covered. You can quickly alter form components such as text and images, and layout. Customize, arrange, and encrypt files, build eSignature workflows, make fillable forms for smooth data collection, and more. Our templates feature enables you to create templates based on paperwork with which you often work.

Moreover, you can stay connected to your go-to productivity features and CRM solutions while dealing with your files.

One of the most incredible things about leveraging DocHub is the ability to handle form activities of any complexity, regardless of whether you require a fast edit or more complex editing. It includes an all-in-one form editor, website document builder, and workflow-centered features. Moreover, you can rest assured that your paperwork will be legally binding and abide by all security protocols.

Shave some time off your tasks by leveraging DocHub's tools that make handling files straightforward.

hi iamp;#39;m dennis and in this video iamp;#39;ll show you how i made this geisha figure on a 3d scroll out of four different types of natural unstained woods and carbon steel epoxy resin i originally planned to use the traditional cnc inlay technique but i ran into several technical issues which i solved with a new optimized prism technique for very precise inlays the inlay technique has been around for quite a while it is based on carving a pocket shape also called female into a board and then a mirrored protruding shape also called male that is usually carved out of wood with a contrasting color this mail piece is glued into the pocket and the excess wood is removed to reveal the shape a bit like those wooden puzzles for little kids but you can immediately see the problem at the corners when using a straight end mill you can cheat a bit with simple forms by rounding the corners but that wonamp;#39;t work for sharp angles or lines that are thinner than the diameter of the bit as