Not all formats, including CWK, are created to be quickly edited. Even though numerous capabilities can help us modify all form formats, no one has yet created an actual all-size-fits-all tool.

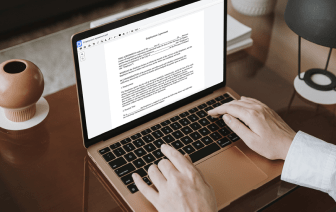

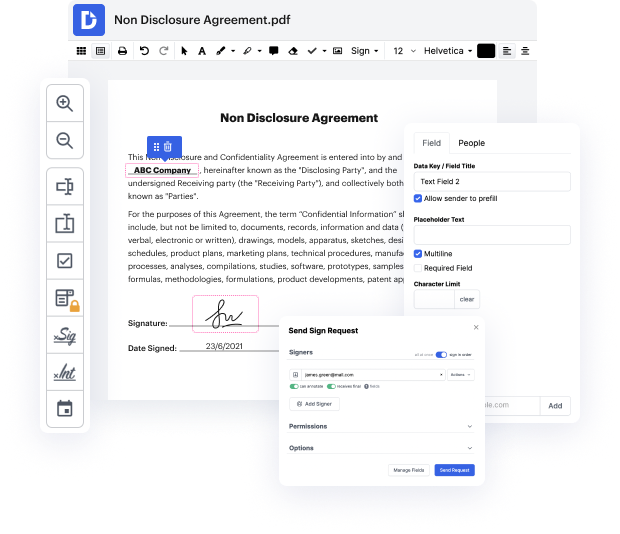

DocHub gives a simple and efficient tool for editing, handling, and storing documents in the most popular formats. You don't have to be a tech-knowledgeable user to inlay attachment in CWK or make other modifications. DocHub is powerful enough to make the process easy for everyone.

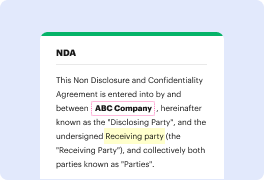

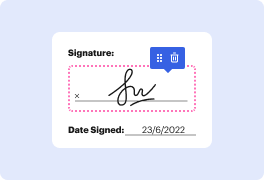

Our feature enables you to change and tweak documents, send data back and forth, generate interactive forms for information gathering, encrypt and shield paperwork, and set up eSignature workflows. Moreover, you can also create templates from documents you utilize frequently.

You’ll locate a great deal of additional tools inside DocHub, such as integrations that let you link your CWK form to a wide array of productivity applications.

DocHub is a simple, fairly priced option to manage documents and streamline workflows. It offers a wide array of features, from generation to editing, eSignature providers, and web document creating. The program can export your files in multiple formats while maintaining highest safety and following the greatest information safety requirements.

Give DocHub a go and see just how easy your editing process can be.

hello and welcome to this vbit inlay tutorial in this tutorial weamp;#39;re going to take a look at a few different ways that you can create inlays by using v bits now for the last few weeks iamp;#39;ve been practicing this and trying out a few methods on my machine and this was spurred by a group of guys in the carve cove facebook group who have been doing these and iamp;#39;ve never done one so i was quite curious about actually trying this out so iamp;#39;m using a really small machine so iamp;#39;ve actually set a few limitations for myself which is iamp;#39;m using a really small machine so itamp;#39;s the same smart 3018 machine so quite a small bed size canamp;#39;t take too much of a depth of cut and i canamp;#39;t obviously ramp the cuts up and get it going really really fast also iamp;#39;m using a 90 degree v-bit now it would be easier if i used a 30 degree letamp;#39;s say 15 60 degree whatever now i could have used one of those but i wanted to use a 90 degree be