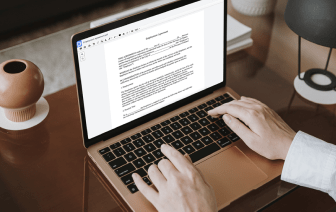

Not all formats, such as 600, are developed to be easily edited. Even though a lot of capabilities will let us modify all form formats, no one has yet created an actual all-size-fits-all tool.

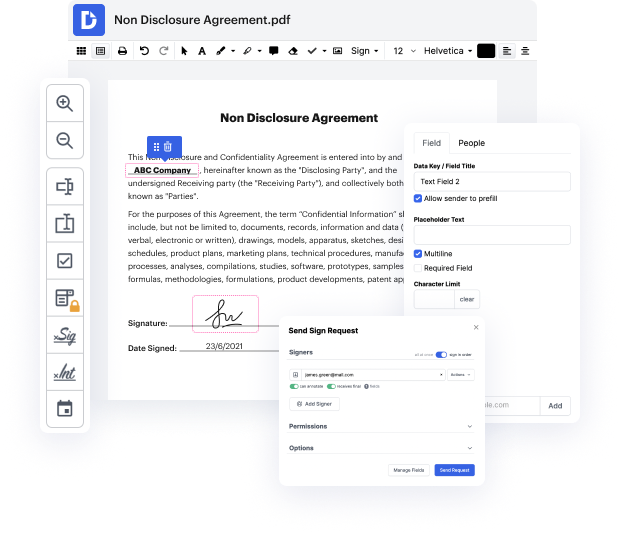

DocHub gives a easy and efficient tool for editing, managing, and storing documents in the most popular formats. You don't have to be a tech-savvy user to inject typesetting in 600 or make other modifications. DocHub is powerful enough to make the process simple for everyone.

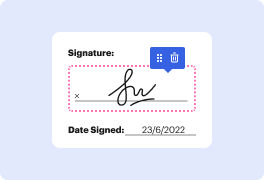

Our feature allows you to modify and edit documents, send data back and forth, generate dynamic documents for information gathering, encrypt and safeguard paperwork, and set up eSignature workflows. Additionally, you can also generate templates from documents you utilize frequently.

You’ll find a great deal of other features inside DocHub, such as integrations that let you link your 600 form to different productivity apps.

DocHub is a straightforward, cost-effective way to manage documents and improve workflows. It offers a wide array of tools, from generation to editing, eSignature services, and web document creating. The software can export your paperwork in multiple formats while maintaining greatest protection and adhering to the greatest information safety requirements.

Give DocHub a go and see just how simple your editing operation can be.

thank you and here is my favorite part about a five axis machine recently we were contacted by a good friend of ours Josh Quintero from Total Industries out in California he just purchased a dvf 8000t exactly like the one we have on our floor [Applause] itamp;#39;s very hot job for that machine so while his machines getting delivered and set up weamp;#39;re going to help them out by creating the process programming fixturing and proving out the first part so check out how weamp;#39;re going to hold this part notice that weamp;#39;ve got a massive dovetail on the bottom of this and the part is just hanging out here in the space we did that for a couple of reasons number one is clearance issue now I wanted to take this stock and seat it all the way down in the box but my problem was the table is so large and the spindle has to come down so far that the spindle was actually going to hit the top of the table because our part actually goes all the way down to rig