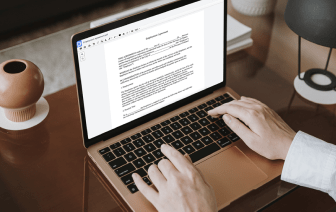

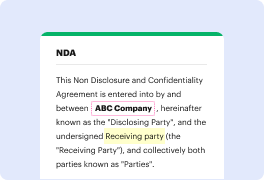

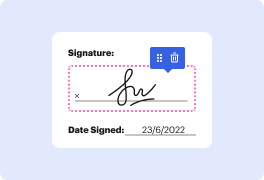

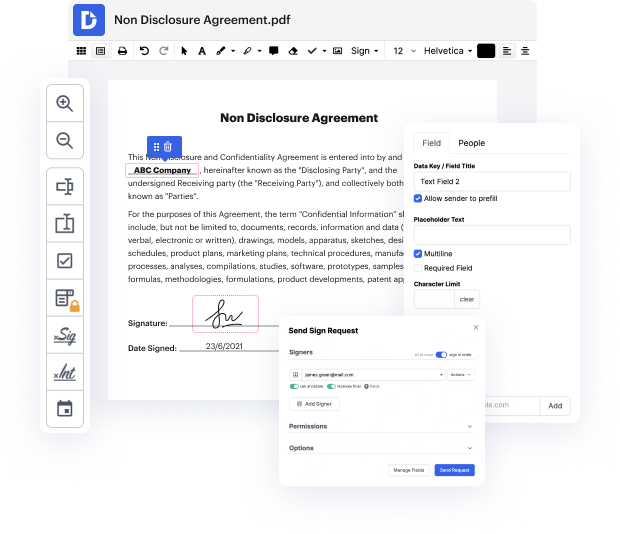

DocHub is an all-in-one PDF editor that lets you inject stuff in raw, and much more. You can highlight, blackout, or erase paperwork components, add text and pictures where you want them, and collect data and signatures. And since it runs on any web browser, you won’t need to update your hardware to access its powerful capabilities, saving you money. With DocHub, a web browser is all it takes to handle your raw.

Log in to our service and adhere to these steps:

It couldn't be easier! Improve your document management today with DocHub!

texture molding of bioplastics in this case the bioplastic has a matrix based on petroleum or renewable feedstock and has organic fillers such as cellulose or wood fibers in this case is important to lower the temperature for example cellulose cannot processed above 205 degrees C otherwise you will see burn streaks on the final materials a part of flow on temperature also lowered the injection speed and check also on the mold side The Gates make them as as big as as possible to have a slow Shear rate as possible too um although we inject lowered all over cooling time and cycle time is the same as with conventional Plastics since we have not that high temperatures maximum 200 degrees C Mill temperature also important drying so materials like wood starch cellulose take up water so use a desiccant dryer and check that your below 0.5 percent in