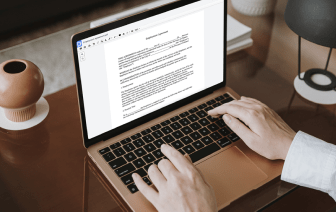

Flaws exist in every solution for editing every file type, and despite the fact that you can find a lot of solutions on the market, not all of them will fit your particular needs. DocHub makes it easier than ever to make and alter, and handle paperwork - and not just in PDF format.

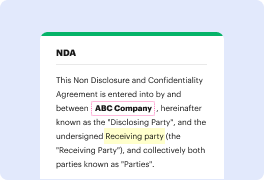

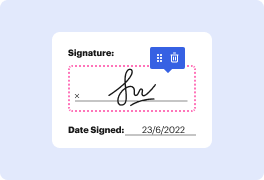

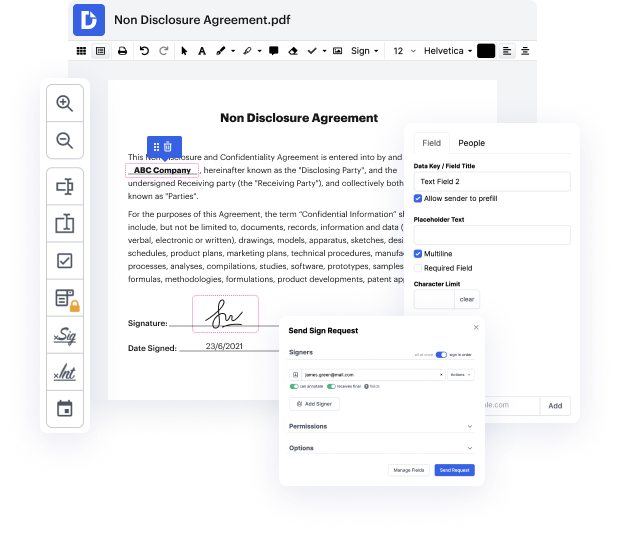

Every time you need to swiftly inject portrait in ODM, DocHub has got you covered. You can effortlessly alter document elements including text and images, and structure. Personalize, arrange, and encrypt paperwork, build eSignature workflows, make fillable documents for intuitive information gathering, etc. Our templates feature enables you to generate templates based on paperwork with which you frequently work.

Moreover, you can stay connected to your go-to productivity features and CRM platforms while handling your paperwork.

One of the most remarkable things about using DocHub is the option to manage document activities of any difficulty, regardless of whether you require a fast edit or more complex editing. It comes with an all-in-one document editor, website form builder, and workflow-centered features. Moreover, you can be sure that your paperwork will be legally binding and adhere to all safety protocols.

Cut some time off your projects with the help of DocHub's features that make handling paperwork easy.

hi welcome to our new video on image r today we will talk about the steps you have to do before you start engraving images on your machine we assume in this video that youamp;#39;ve already aligned your laser mirrors perfectly first letamp;#39;s talk about what we will do in this video we will find out the sweet spot of your laser also called the focal length we will do a ramp test together to achieve that then we will find out the needed dpi for your future images so letamp;#39;s get started what we need a piece of plywood a digital caliper a small piece of acrylic all files youamp;#39;ll see in this video are attached as download in the video description enhance one side of the plywood by putting something underneath of it now we will move our laser head to the highest position of the plywood load a solid line file in your laser software if you have issues with that you can use the file i used the download is in the video description we will set the power to get a clean s